In the year of 2023, GETO, the “1+N” one-stop solution provider, has worked with international clients to create a series of excellent construction projects. We selected 7 of the most representative projects, let us take you to enjoy the charm of green and smart buildings.

As China proposed the joint construction of the “One Belt One Road” initiative, which laid the foundation for good business cooperation between the two countries, GETO actively assisted in the construction of local affordable housing and infrastructure.

Project Highlight:

▪ The project is about 130 apartments and affordable houses.

▪ PC and traditional wood formwork and other processes are still the main construction methods in the local market, and local customers and labor workers are not familiar with aluminium formwork. GETO provides engineering guidance services for supporting products to help laborers use the products smoothly and improve the local market’s recognition of aluminium formwork.

▪ GETO provides customized design solutions to suit the characteristics of local houses, such as low-rise villas with thick walls.

This project is one of the longest main spans of its type in Southeast Asia. Once completed, the project will connect to the coastal highway, effectively improving local transportation and driving surrounding economic development.

Project Highlight:

▪ The total length of the bridge is about 4693m, the bridge length is 2390 meters (of which the main bridge is 1110 meters long), and the bridge deck is 12.4m wide. The bridge structure has the characteristics of ultra-long pile foundation in water, large pile cap, high piers, and extra-large span.

▪ GETO is glad to provide the cofferdam, pier, and bent cap etc to ensure project quality with many unfavourable factors such as urgent construction schedules, complex construction environment, etc. GETO overcame them all and provided our on-site engineering guidance to ensure the smooth use of products.

The project is located in New City Zone A — Area A3,Macao. It is an important livelihood project. Covering an area of 11,668 square meters, it mainly includes approximately 754 residential units, public parking lots, and commercial and social facilities. The project uses prefabricated concrete and metal formwork for construction of green construction.

Project Highlight:

▪ In the GETO production base, We provide pre-assembly service of aluminium formwork with PC components.

▪ GETO aluminium formwork is flexible and can be combined with many systems such as timber formwork/ PC components to achieve good pouring effect, and the optimal solution with the lowest comprehensive cost.

The project has two buildings, they are 148 meters high and 122 meters high respectively, providing 0.24 million square meters of office space. The project is strategically located atop a high-speed rail station and close to several major transportation lines. It has marvellous transportation advantages and connects major cities on the mainland to other parts of the world.

Project Highlight:

▪ It is an exclusive-customized solution provided by GETO. Its structure is a big project that is composed of aluminium formwork of 30,000 square meters of construction area at once.

▪ Among them, arc and cylindrical panels account for 5%; customized non-standard parts for 10%; and 13+ aluminium formwork structural change layers are included.

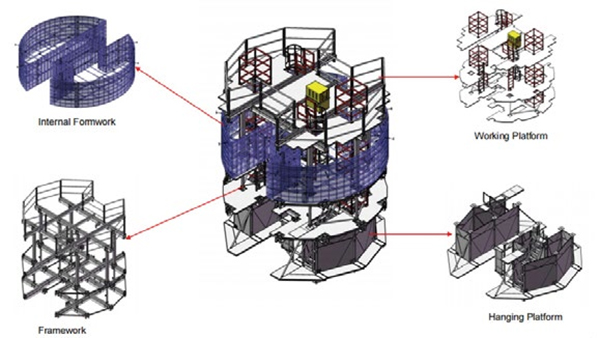

The project contains a 50 km tunnel across the southern and western regions of Singapore. It is an important part of the local drainage integration system. GETO provided the shaft formwork system for this project help to solve the drainage problem.

Project Highlight:

▪ This product has many advantages such as fast construction speed, high safety, high degree of mechanization, and labor saving.

▪ Each jacking operation only takes 2 to 3 hours.

▪ The steel platform of the top formwork system has large overall rigidity and large bearing capacity. The platform bearing capacity reaches 10 kN/㎡.

▪ The measurement control points can be directly projected onto the steel platform for construction measurement convenience.

GETO comprehensively considers factors such as construction convenience, comprehensive cost, and high product turnover rate to develop a tunnel formwork system for customers. It is also the fastest and most economical way to build high-quality earthquake-resistant apartments, villas, student dormitories, and hotels. Currently, GETO provides tunnel molds made of steel and aluminium for customers to choose from. Steel tunnel formwork is used in this project.

Product Highlight:

▪ Simple formwork process, low labor force;

▪ Tightly spliced, not easy to deform;

▪ Good integrity of formwork, strong seismic resistance;

▪ Good insulation performance, conducive to winter concrete insulation;

▪ Large formwork dismantling, high level of mechanization, good safety performance.

Savana is a majestic 36-storey serviced apartment that stands as part of the iconic Utropolis at Batu Kawan. It will offer 522 units of condominium after finishing.

Project Highlight:

▪ The self-climbing platform is 9 meters high, equivalent to 2.5 standard floors, large scale.

▪ The project is located close to nearby residential buildings, making construction difficult and requiring high self-climbing platform installation requirements.

▪ Customized solutions, covering the residential building part of the project as required, saving costs for client.