As a result of dedicated research and development, the latest panel design of GETO – UT600 has its durability greatly improved from its previous version (U600). The tensile strength of the UT600 panel is equal to or more than 260Pa, while the bearing capacity is 60kN. The maximum deformation rate of using the GETO aluminium formwork system has been reduced by 15%, from 2.568mm max (U600) to 2.193mm max (UT600). As the outstanding China aluminum formwork factory, GETO devotes itself to technology innovation.

This indicates that the bulging possibility of the aluminium panel upon the completion of casting is lower, resulting in higher reusability of the aluminium formwork system on the sites. Contractors and project managers understand well that successful deformation rate control will contribute to significant project cost savings and reduction in on-site labour intensity. With a smaller deformation rate guaranteed, the verticality and horizontality of the casting results for time being is close to perfection, forming s right-angled and non-defective structure.

Meanwhile, horizontal structure bonds are attached to a pair of vertical structure bonds of every aluminium formwork panel by overhead welding. This welding technology is chosen to further strengthen the GETO formwork systems, as the welded area will be minimized and consequently creating less aluminium panel area to be affected by heat impact caused in case surface welding technique is adopted. This technology is tremendously significant for the production of aluminium formwork systems since welded area affected by the heat impact will result in the reduction of panel strength by half (if compared to the unprocessed formwork system). With overhead welding in place, lesser time is the cost for the welding stage in panel processing, contributing to lesser labour intensity in production, and lower processing cost.

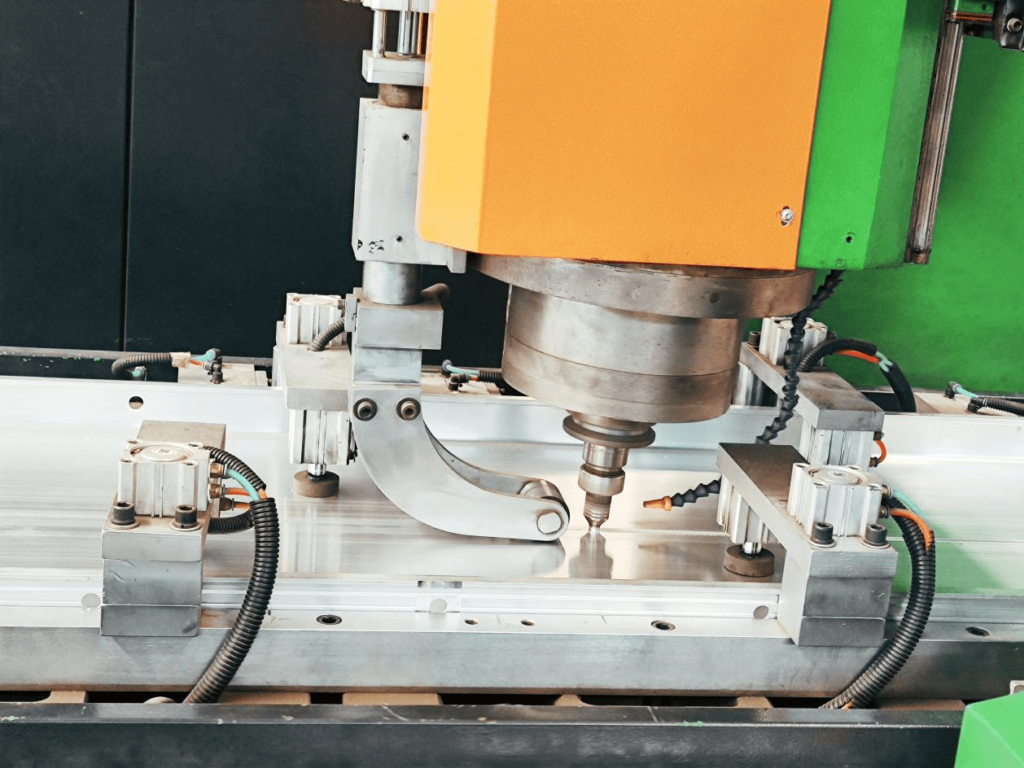

Friction stir welding is a solid-state joining process that uses a non-consumable tool to join two facing workpieces without melting the workpiece material. Its reliability and efficiency have been more and more widely acknowledged in a variety of industries. GETO is the first Chinese aluminium formwork manufacturer that applies such innovative technology in aluminum formwork production.

With friction stir welding to produce welds with very uniform mechanical properties but minimum distortion, GETO, providing a reusable aluminum formwork system, is so proud to provide customers with aluminium formwork of high durability and nice performance.

The mindful design and production technology of GETO aforementioned can deliver cost advantage to honorable clients, creating guaranteed high-quality and cost-controlled China system aluminium products.

Published: Jan 30, 2023

Last published: Jan 17, 2023