GETO Malaysia participated in a significant landmark project in the middle of Genting Highland, wellknown summer retreat in Malaysia. It is IBN Highlands City – A billion-dollar project developed by IBN Corp Ltd. GETO empowers the construction industry around the world with high aluminium formwork productivity.

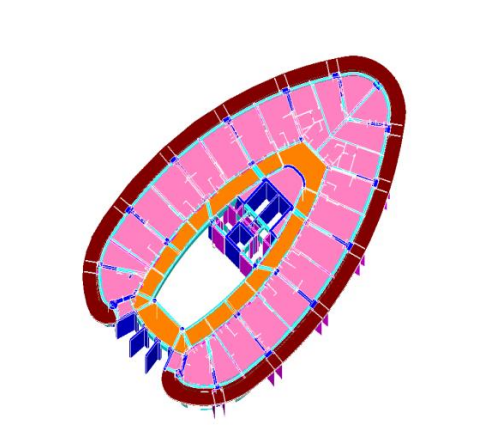

IBN Highlands City is a mixed development project (serviced apartment and hotel), which was designed based on the imaginative visuals of several pieces of flower petals placed in the midst of clouds of the cooling highland. The project has a total built-up area of 8,400,000 sq ft.

Within the 4978.52 ㎡ aluminium formwork construction area the project consumes in total, GETO Malaysia supplied 2166.83 ㎡ of the aluminium formwork system. In the system, GETO Malaysia supplied 400 ㎡ systems, which are round edges and arc-shaped columns. The special design of IBN Highlands City that is largely different from common typical structures creates challenges for the construction and precise design of formwork in aluminium factory for the project.

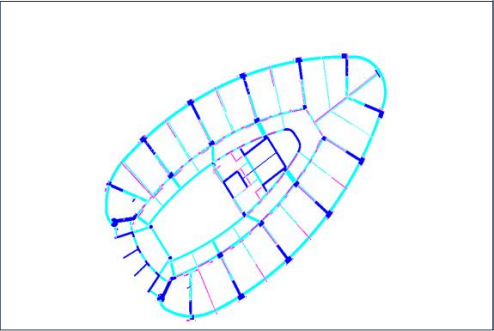

With GETO’s intelligent formwork software, BIM Modulation Design in place, special structures are no longer a real challenge since every structure in the AutoCAD drawing of IBN Highlands City can be quickly checked in place at one time. This patented software of GETO Group can automatically identify walls, beams, slabs, and other structures with 100% precision attained.

In addition, GETO’s intelligent BIM Modulation Design Software can facilitate the client to achieve an ideal state in maximizing the reusability of the client’s existing aluminium panel in adoption together with the GETO aluminium formwork system.

Upon the delivery of the aluminium formwork system to the site, GETO site supervisors stayed with the project for at least one month. They are committed instruct the workers on site to appropriately fix the structure system, while quickly responding to any circumstances related to the formwork system on-site. Because of our outstanding construction engineering solutions, we have done a great job with this project.

Besides the use of the standard panels supplied, the curve-shaped structures formed by special-shaped aluminium formwork systems are in good casting effect as well. This helps the contractor to save up time for crafting the special-shaped by crafting timber formwork on-site, which brings the result of cost-saving in hiring increasingly costing labour in carpeting. Also not forget to highlight, the high durability of the GETO Aluminium Formwork System guarantees the consistency of the casting quality of the project across numerous floors it is being reused.

Published: Sep 30, 2022

Last published: Sep 17, 2022

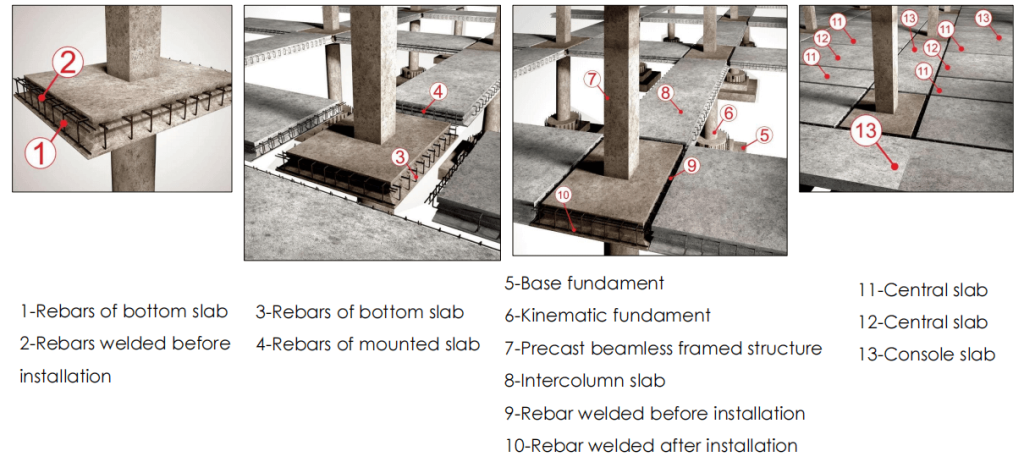

One of GETO’s customers has studied special building structures to protest against earthquakes. Their company mission is to provide solutions to save lives and deliver affordable housing in earthquake-prone areas. Finally, the local government highly appreciated and recognized their building solution, which adopted the GETO Precast Concrete.

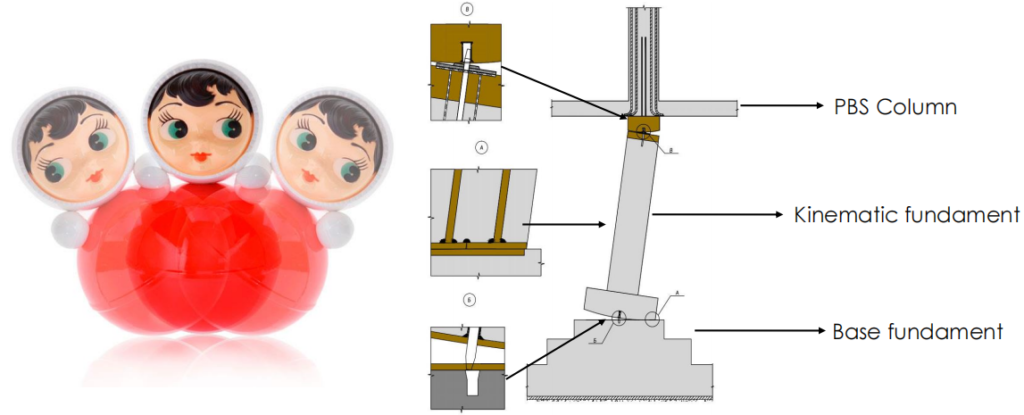

Seismic isolated fundamental work on the same principle as a“tilted doll”. Unlike other seismic isolation system, it doesn’t require any regular maintenance. GETO Precast Mould System helps clients save a lot of money for later maintenance.

The clients provide the architectural plan, elevation plan and section only, there is no structural plan, because it’s beamless structure. However, they require us to provide aluminium forms for the column parts. it’s not the same as normal square columns. The difference is that we need to reserve several holes for steel rebar and those holes should be open precisely, here let me share some attached photos from GETO precast factory. Our customer calls it as “PBS” column.

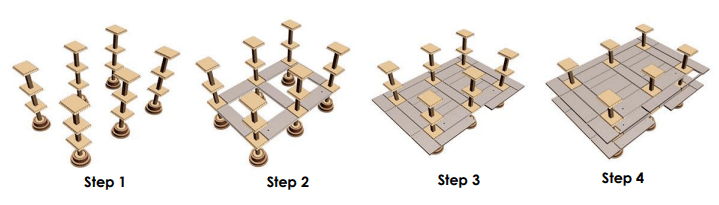

This precast formwork system has two main components that can be used independently. The factory produced precast columns and precast slabs are combined and welded on site. No beams are required that reduces building weight, cost and time of construction.

Published: Sep 17, 2022

Last published: Aug 30, 2022

In Taiwan, China, the government is planning new MRT stations, of which the Sanying MRT station is under construction. GETO has proudly supplied aluminium formwork system for wall, beam, deck, column etc, including inclined columns.

The dimensions of the largest inclined column on site are as follow:

Length of column base section: 2300mm

Width of column base section: 2300mm

Vertical height of column: 14253mm

Length of beveled side of column: 15222mm

Angle: 69.45°

MRT are closely related to people’s lives and being able to build MRT stations with aluminium formwork is an important step forward in GETO’s involvement in public construction projects in Taiwan.

In this project, due to the special structure, it is necessary to adopt large leaning columns, which are more difficult for our aluminium formwork design, but we did it perfectly.

Large leaning columns mean that stronger support and reinforcement systems, more accurate design and production, and strict site management are required – all three of which are essential.

① GETO solves it with tie rod system, which ensures the security and efficiency of the project. GETO formwork class products can be applied to different project types and high turnover of formwork between different structure types and typical floors can be achieved.

② GETO uses self-developed software of modulation, such as BIM, Auto CAD and 3D Modulation Software to offer the clients. These technologies provide technical support for the customer’s project, promoting it to be successful.

③ In this project, GETO provides 24 hours online technical support for customers to solve the technical problems when using our aluminium column formwork, so as to be customer-center and give customers a good experience.

Published: Aug 30, 2022

Last published: Aug 17, 2022

This project consists of 11 towers, formed by 2444 precast modules of 91 structural types. GETO supplied 35 sets of automated precast mould and 17 sets of non-automated precast mould for turnover in casting in this project.

GETO supplied 21 sets of automated precast mould for turnover in casting 38 precast modules in this tower.

Related article:

https://www.getoformwork.com/industry-news-articles/ppvc-housing-precast-formwork-system-geto/

https://www.getoformwork.com/enterprise-news-articles/geto-ppvc-housing-precast-formwork-system/

#PPVChousingprecastformworksystem

Published: July 17, 2022

Last published: June 30, 2022

Upholding the business philosophy of customer-centric, GETO and its partner collaboratively committed into product development and upgrading works for the successful introduction of

GETO offers the following services:

Advantages:

Advantages:

Advantages:

GETO prefabricated mould system, compared with traditional construction technology, has unique four advantages:

Housing precast production formwork can form all struction of a building, including the deck, side wall, base floor, door opening, and window at one time, thus minimizing duration for the precast structure formation. Compared with the traditional steel formwork, it has over 50% enhancement in working site efficiency.

Ease site labour’s working intensity, while offers more assurance for construction workplace safety.

The green, low-carbon, and highly automated operating environment, in line with the trend of global low-carbon economy and the green building concept advocated by governments of various countries, is gradually replacing the conventional construction technology.

Related article: https://www.getoformwork.com/industry-news-articles/geto-ppvc-housing-precast-formwork-system-2/

#PPVChousingprecastformworksystem

Published: June 30, 2022

Last published: June 17, 2022

As an

For a tower with two types of typical floor design, GETO’s solution is to offer one set of aluminium formwork system for reuse and turn over throughout the tower. GETO equips its self-developed 3D BIM System to do automatic formwork modulation, correction and design. The integration of top-notch technology has made the formwork system design to reach the standard of no physical aluminium formwork mockup needed. The solution is more

There is a great difference in terms of structural design and floor height between podium and typical floors in a tower. With rich experience and professional strength accumulated from the past, GETO can offer one set of aluminium formwork system that could be turnover and reused between non-typical floors and typical floors, by the efforts of modifying structural design of the project and enhancing the standardization level of aluminium formwork system set. Meanwhile, we propose aluminium-timber mix and formwork strengthening solutions to our clients, as to facilitate our clients in saving up construction material and labour cost, which consequently solve the pain point of our clients in bearing high cost to procure extra set of formwork for non-typical floor construction.

For construction projects that consist of huge and flat structure without beams, GETO will introduce them to use Quick-Deck System with 1200 x 1800mm in its formwork size to build podiums. The operational efficacy for this system is high, which can effectively speed up the progress of construction sites and satisfy the quality control needs of our clients, and facilitate them to minimize integrated cost for their

By offering integrative design of aluminium formwork system and self-climbing platform system, GETO can contribute to improve the efficacy of structural work progress for

Based on the project characteristics of terrace house project and the budget allocation of relevant client for the number of formwork sets, GETO offer customized aluminium formwork system turnover solution for clients. By modifying structural design of terrace houses project and improving the standardization rate of formwork system, GETO proposes technical solution for aluminium formwork system turnover that takes mirror-like structure and party walls into account. This effort can maximize the turnover rate of aluminium formwork system invested by our clients.

GETO has dealt with extremely difficult projects previously, by involving in detailing and design, and production process of projects with complex structures, including round columns, arc-shaped beams, decks with special angles, etc. Even if buildings with unique designs have great floor height, more changes, and complex structures, GETO can still manage to design it with zero-flaw standard by utilizing its self-developed Intelligent Formwork Modulation System.

In adherence to the industrialization of construction industry concept proposed by Singapore Government, GETO and its regional partner collectively developed innovation in crafting PPVC precast system. This innovation classified the rooms in every housing units as one modular unit for one-time molding in a precast production plant prior to delivery to construction sites. In the process of precast production in plant, GETO PPVC Fully-Automated Formwork System Machine is used to assembly and detach building formworks and support frames. Facilitated by intelligent automated alert checking system, every modular units are assured to be in effectively strengthened status, which is align with the strict requirement of Singaporean Government to allow only 1mm error for every meter of building precast structures.

With the principle of customer-centric spirit, GETO maximized the turnover and utilization rate of the aluminium formwork for the public buildings like station, school, etc, by modifying the architectural drawing of the project. The basement and typical floors of the public buildings was completely constructed by using aluminium formwork,

Please feel free to contact us to discuss more creative engineering projects. Click on the page to know more about

Published: June 17, 2022

Last published: May 31, 2022