Advantages

Safety

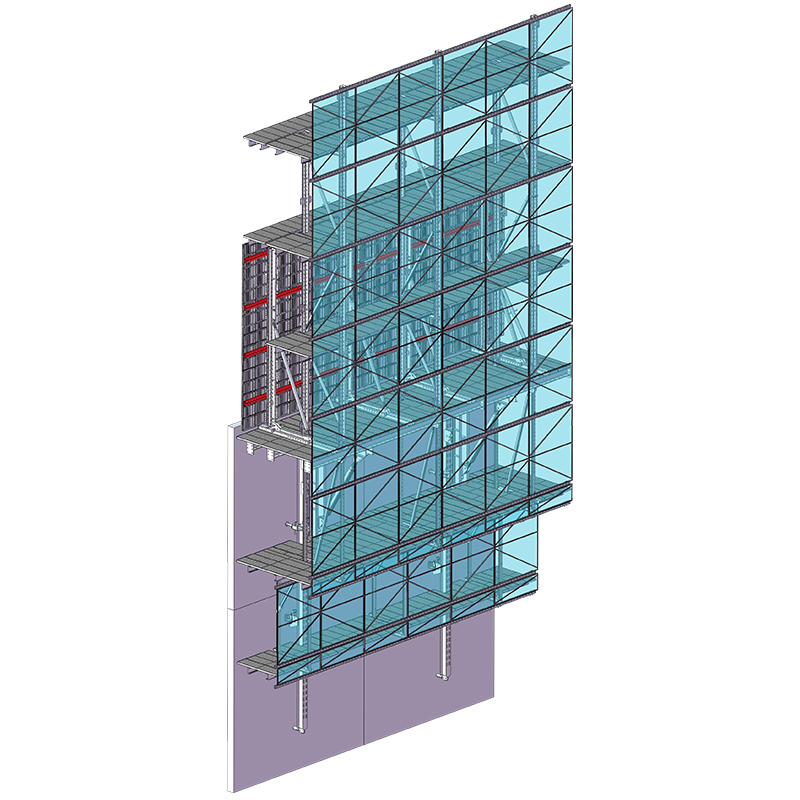

- Fully steel-hardened design improves the structural stability, reliability, and fire resistance of climbing bracket.

- Formwork retraction gear reduces construction risks and effectively prevents grout leakage from the formwork traveling device.

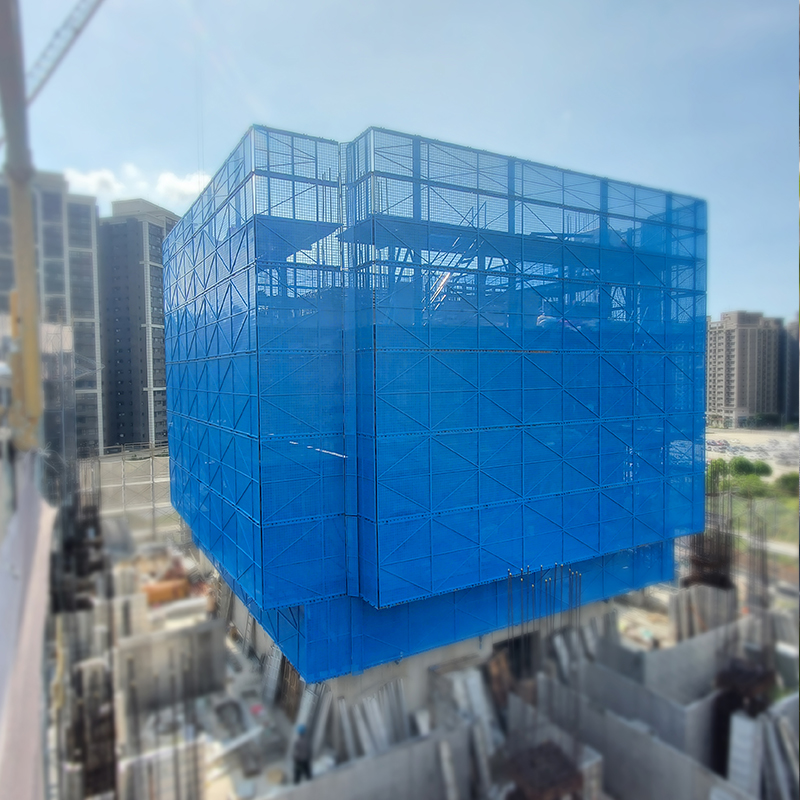

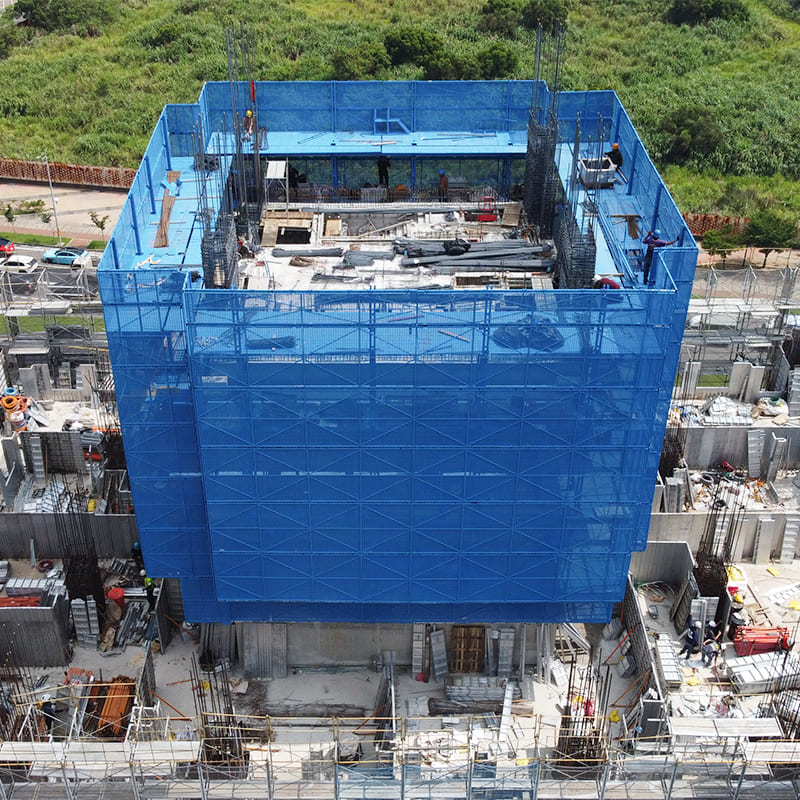

- Climbing bracket utilizes fully enclosed steel protective screening.

- Vertical and inclined hydraulic climbing options ensure a smooth, synchronous, and safe.

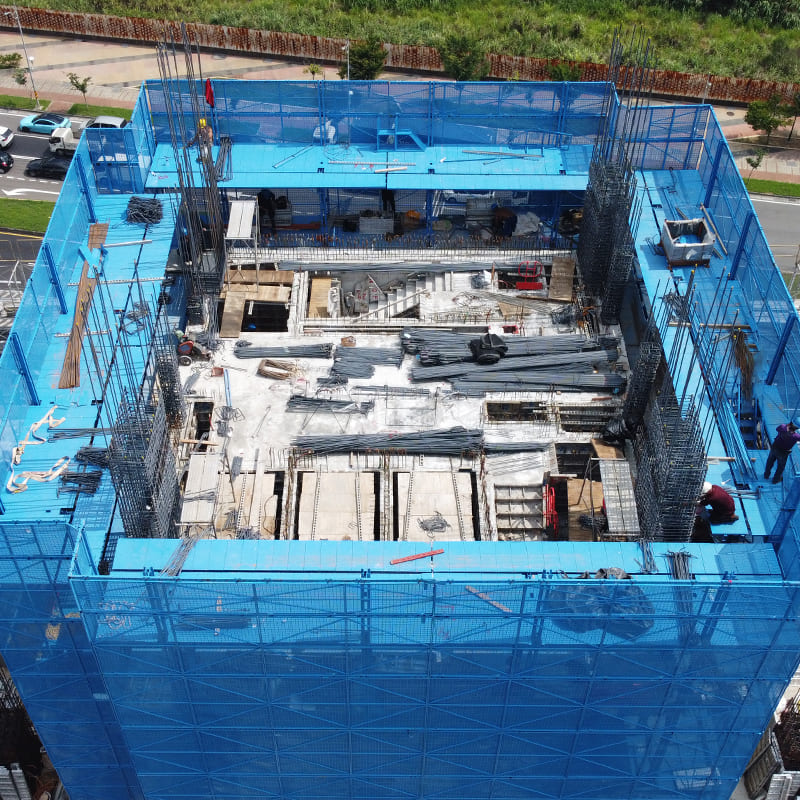

- Rebar installation platform is synchronized with climbing.

- ensuring safe operations.

Highly Cost-Efficient

- Providing all-round operational platforms saves materials and labor.

- After low-level assembly, the climbing bracket continuously climbs to the top, reducing formwork damage.

Convenience

- Modularizing the protective screening for easy installation and transportation.

- Each platform are fully steel-hardened, modular pedals for convenient transportation and easy installation.

- The climbing formwork self-climbing with formworks, enabling direct adjustments and cleaning on the climbing bracket, without requiring crane lifting, scaffolding, or level-by-level alignment.

- The bracket can be climbed both integrally or separately.

Technical Data Of GTP100 Automatic Hydraulic Climbing Formwork System

|

S/N |

Item |

Specification |

|

1 |

Lifting Capacity (Single-Unit Climbing Platform) |

100kN |

|

2 |

Segmented Standard Pouring Height |

3.0m-5.5m |

|

3 |

Maximum Climbing Height |

5 min/m |

|

4 |

Influence Width per Bracket |

About 4m (Subject To Project Specifics) |

|

5 |

Working Platform Width |

2.4m |

|

6 |

Max Inclination |

+/-10° |

|

7 |

Driving Force |

Hydraulic Power |

|

8 |

Wall Formwork System |

Aluminium Formwork/Steel Formwork/Timber-Beam Formwork |

Operating Conditions

Conditions for climbing formwork construction an dclimbing:

- No severe weather conditions (e.g., thunderstorms, rain, snow,fog,frost, haze,orhail) during operation.

- Basic wind pressure does not exceed level 5 (approximately24.5-28.5 m/s).

In wind speeds over level 7 (approximately 13.9-17.1 m/s), typhoon reinforcement measures are required for the climbing formwork bracket.

*Note: Referring to the technical standards outlined in the Technical Standard for the Hydraulic climbing Formwork Engineering of the People's Republic of China.