GETO provides a complete range of formwork systems designed to improve efficiency, safety, and quality across modern construction projects. With years of expertise as a global formwork manufacturer, GETO delivers solutions that combine precision engineering, high reuse rates, and adaptability, making them suitable for high-rise buildings, infrastructure works, basements, bridges, and modular housing.

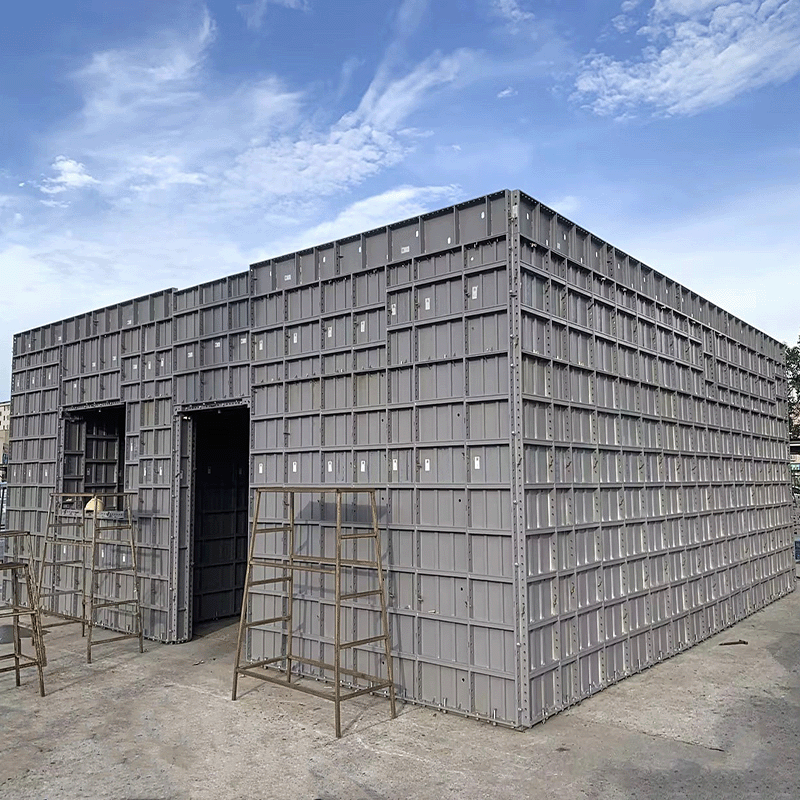

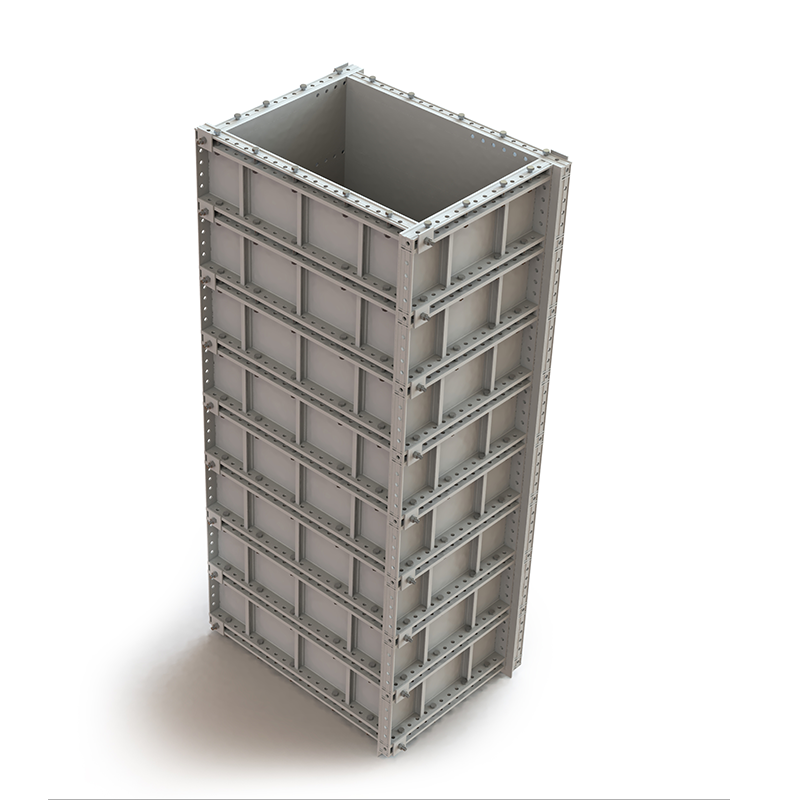

Our aluminum formwork system is the flagship solution, widely recognized for its lightweight structure, high durability, and ability to deliver smooth concrete finishes with exceptional verticality and flatness. Aluminum formwork significantly shortens construction cycles, reduces labor costs, and ensures sustainable use through its high reusability.

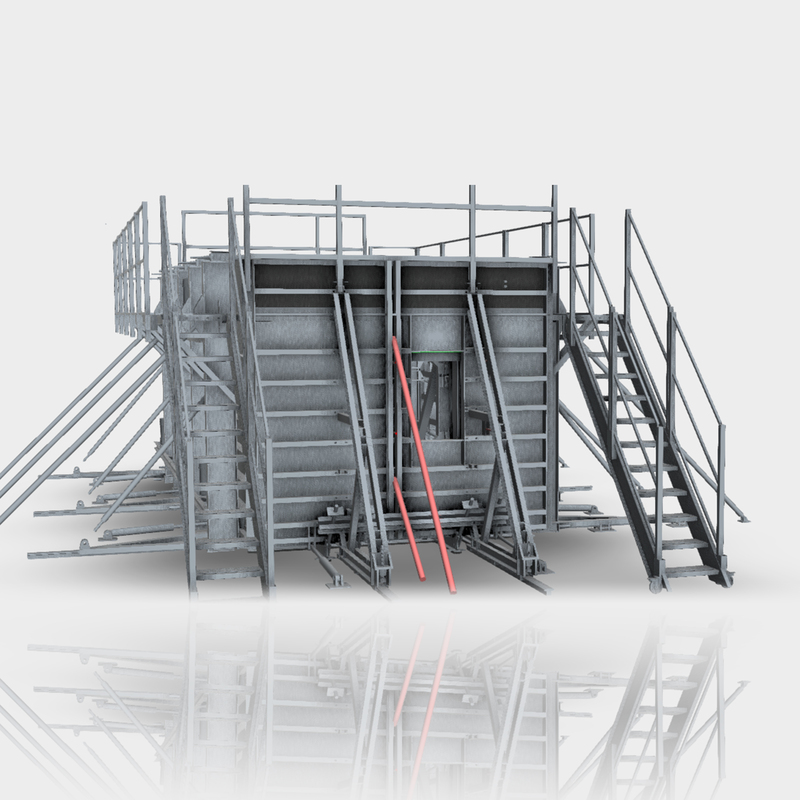

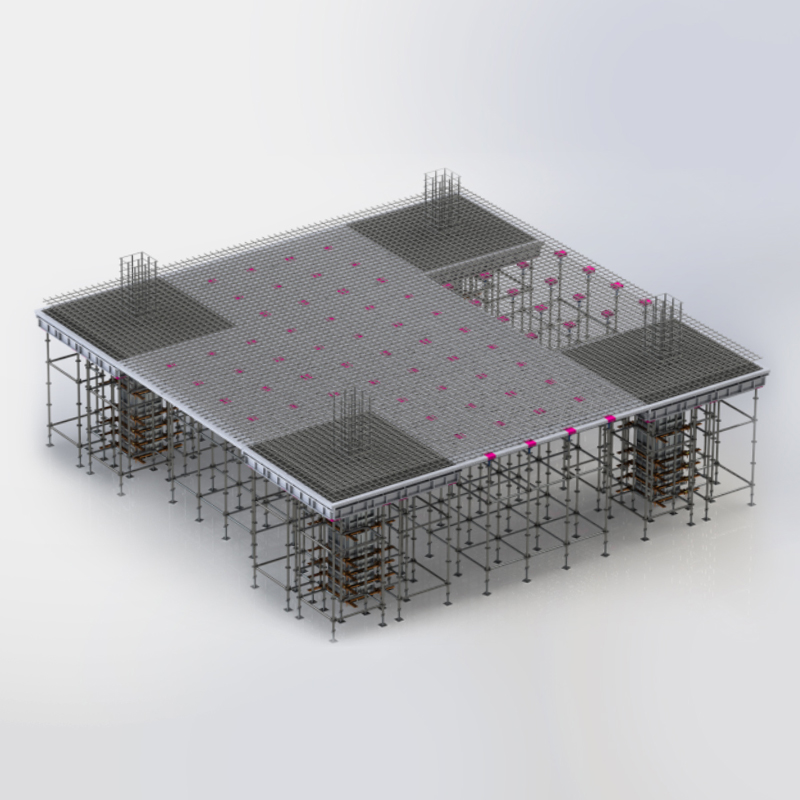

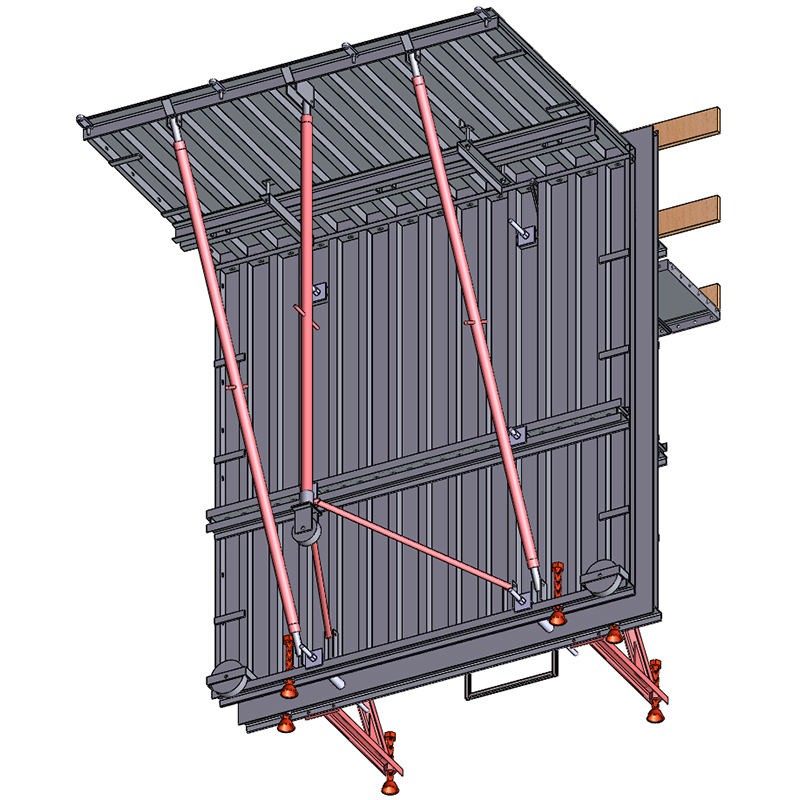

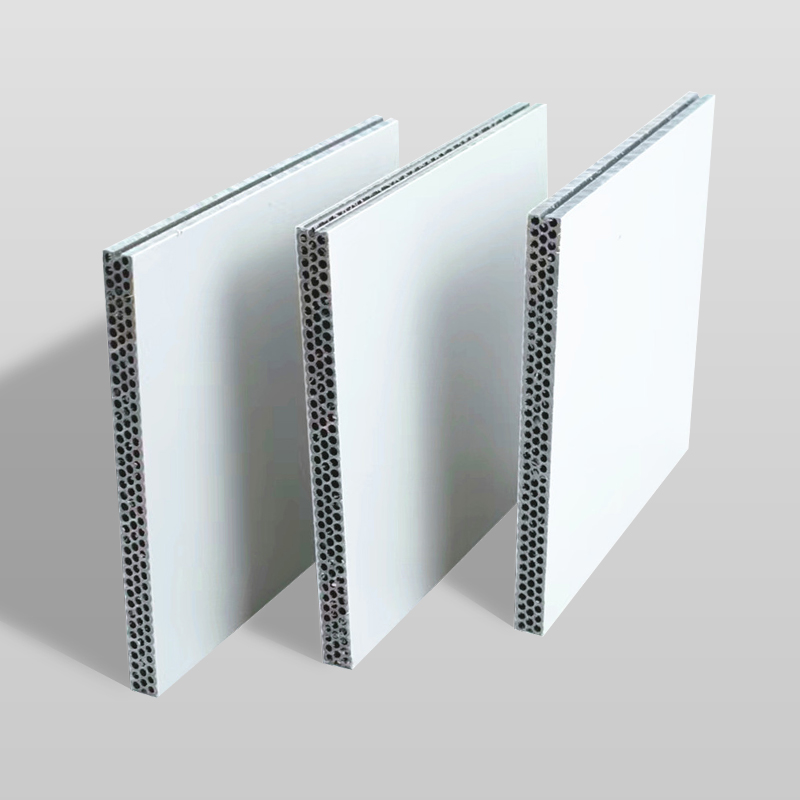

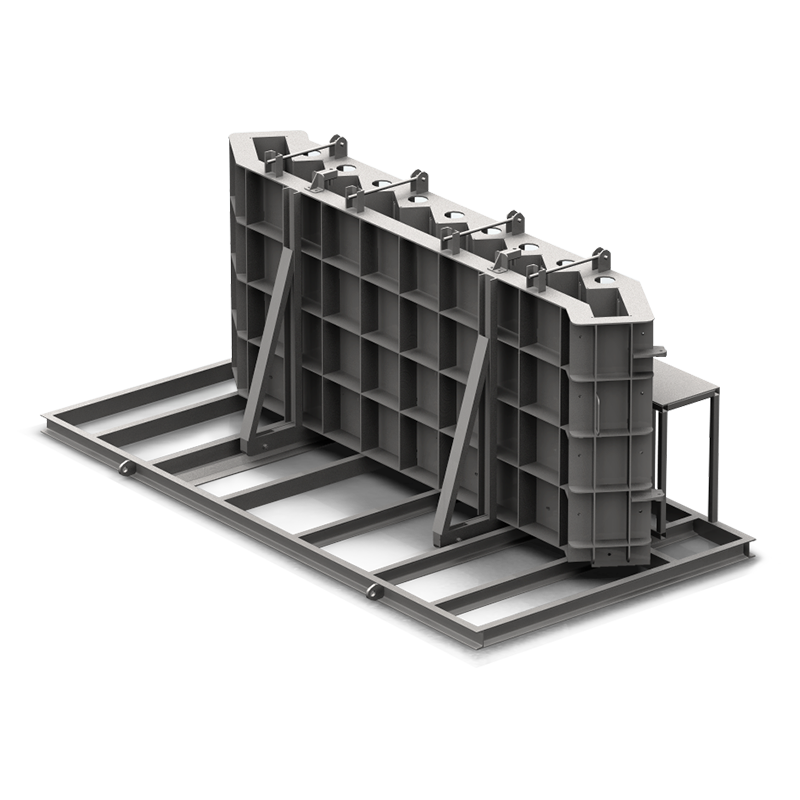

Beyond aluminum, GETO also develops innovative formwork technologies tailored to specific applications. From precast and PPVC housing molds for modular building, to deck and table formwork systems for large-area slabs, and tunnel or single-side wall frameworks for specialized projects, each solution is engineered to meet diverse construction requirements. For projects with unique structural needs, steel-framed timber, plastic, and bridge formwork systems provide reliable alternatives that balance cost, strength, and flexibility.

All GETO formwork systems undergo strict quality control and can be customized to project specifications, ensuring seamless integration with different building types and construction methods. With features such as high load-bearing capacity, quick installation, and long service life, our formwork systems are trusted by real estate developers, contractors, and government projects worldwide.

By combining standardization with customization, GETO helps you achieve faster construction cycles, reduced material waste, and higher-quality results—making our formwork systems a dependable choice for projects of every scale and complexity.