In large overseas construction projects, time, safety and reliability are key factors to ensure smooth project delivery. GETO has tailored a professional and complete scaffolding solution for EPC contractors and international builders - the interlocking scaffolding system.

Why Modern EPC Contractors Prefer Ringlock System for Overseas Projects?

At a project site in the Middle East with a temperature of 50℃, the EPC general contractor received an urgent task: to complete the construction of a 500㎡ working platform within 48 hours for the installation of hoisting equipment and pipelines.

The construction period is tight, the surface is hot, and the labor is tight. Any delay will trigger a chain reaction. At this time, will you still choose traditional fastener scaffolding?

This is the problem that many EPC contractors are facing - short construction period, expensive labor, high safety standards, and the project must span extreme construction environments such as Africa, Southeast Asia, and the Middle East. The emergence of Ringlock System is born for these "high-difficulty, cross-regional" modern engineering projects.

As a complete set of modular scaffolding system solutions tailored for overseas construction environments, Ringlock System has the following advantages:

1. Modular design, on-site construction efficiency increased by more than 30%

2. High-bearing capacity structure, meeting the construction requirements of large bridges, subways, and industrial plants

3. No bolts or tools required, fast installation and disassembly, reducing dependence on professionals

4. For Malaysia, GETO holds certification to streamline the project review process

In short, shoring system such as ringlock system is helping more and more EPC general contractors achieve on-time delivery, reduce labor costs, and improve on-site safety and other construction goals around the world.

Ringlock System vs. Traditional Scaffolding Systems: The Differences That Really Matter

| Feature | Ringlock System | Cuplock / Frame / Tube & Clamp |

|---|---|---|

| Assembly Speed | Fast (no bolts, tool-free) | Slower, manual clamps or cups |

| International Compliance | EN12811, OSHA | Often uncertified or local standard |

| Durability | Hot-dip galvanized, 8+ years life | Powder coated or painted, prone to rust |

| Load Bearing Capacity | High (heavy-duty) | Medium to low |

| Export Adaptability | Stackable, detailed packing list | Mixed components, harder to consolidate |

Ringlock scaffolding for building construction

Advantages of the Ringlock system: Designed for difficult construction projects

It is particularly suitable for the following engineering scenarios:

Bridge and highway construction

Modular Ringlock Scaffolding can build a large-span support tower structure, which is suitable for construction environments with high requirements for strength and stability.

In addition, the Ringlock Scaffolding System adopts a modular structure, which is not only convenient to build, but also extremely strong, which makes it easy to cope with the high-intensity loads in cast-in-place concrete construction.

Therefore, the Ringlock Frame System is widely used in construction projects such as bridges, tunnels, and floor slabs as a support formwork for large structures.

At the same time, in actual work, the Ringlock system has complete components and perfect specifications. Workers can quickly disassemble and move to the next construction section, which greatly improves the efficiency of phased operations.

Oil, gas and power plants

Ringlock Support System can be used in the construction process of large industrial buildings such as oil, gas and power plants. For construction environments with high safety levels and high heavy load requirements, the Ringlock system can also stably play its role.

This is due to the advantages of the Ringlock Platform System's stable structure and flexible construction. Especially when building a maintenance platform in a high-altitude environment, the Ringlock Scaffolding System enables engineers to complete special operations such as maintenance, welding and equipment replacement more safely and efficiently.

Construction of subway passages and tunnels

During the construction of subway passages and tunnels, the Ringlock System, with its flexible connection method and high-strength support capacity, perfectly meets the construction needs of various circular or curved structures.

For more special structures such as arch support, curved walls or special-shaped sections, the Ringlock Scaffold Structure can also be built accurately and quickly.

Compact space

In a construction environment with a relatively compact space, such as equipment rooms, underground pipe galleries or structural cavities. The Ringlock Scaffolding System can also be easily built because its components are easy to install and each part is linked together.

This flexible and stable connection accessory enables the Ringlock Support System to be quickly installed and disassembled, and used in multiple operating areas in turn.

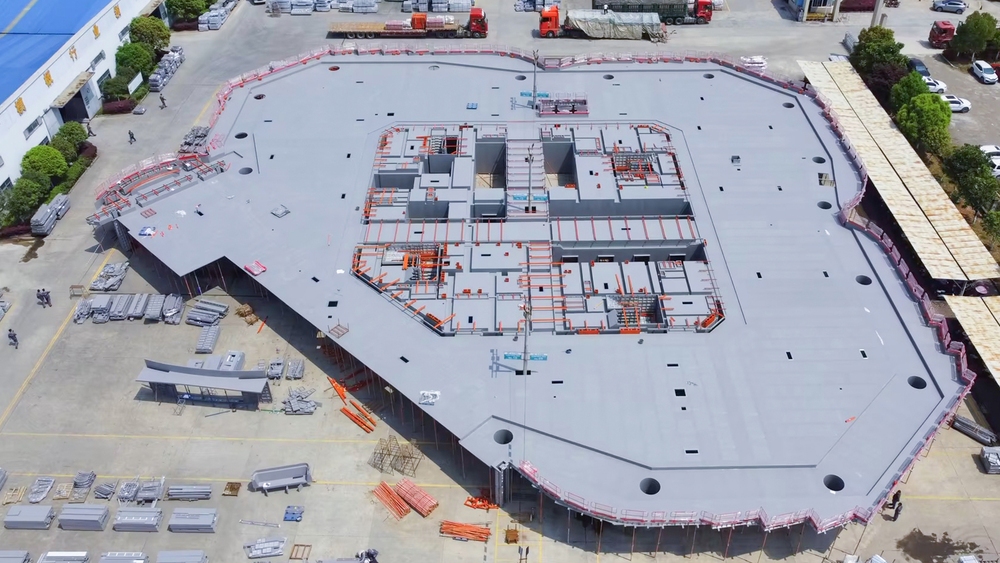

Modular buildings and prefabricated factories

The Ringlock system is compact in design and easy to assemble. It is quick and neat to install. There is almost no welding and cutting required during the entire construction process. During installation, it can minimize interference with other processes.

Exterior walls and roofs

The Ringlock Platform System can also be used as a safe working platform for exterior wall and roof operations. Its structure is stable, safe and reliable. In particular, the modular design enables construction workers to flexibly adjust the platform height to meet the needs of operations on different floors or slopes, which greatly improves the safety and efficiency of aerial operations.

Special equipment installation

Most of the components of the Ringlock System are made of high-strength hot-dip galvanized steel, which has good heat resistance, corrosion resistance and chemical corrosion resistance. Therefore, it is suitable for industrial scenarios with strict environmental requirements such as petrochemicals, electricity, and pharmaceuticals.

Conclusion: Future-proof scaffolding solutions to help you meet global construction challenges

Faced with increasingly complex cross-border construction needs, Ringlock scaffolding systems stand out as future-proof, integrated scaffolding solutions for EPC contractors around the world.

Whether it’s the scorching deserts of the Middle East, the tight deadlines of bridge projects in Africa, or the demanding construction requirements of tunnels in Southeast Asia, ringlock scaffolding systems can overcome the shortcomings of traditional scaffolding systems.

With its modular design, excellent load-bearing performance, tool-free assembly, and compliant safety standards. It is suitable for a variety of complex construction engineering scenarios, from cast-in-place concrete supports and aerial maintenance platforms to compact machine rooms and prefabricated construction sites. Modular Ringlock Scaffolding has become a must-have system for modern construction contractors to reduce labor costs, improve safety, and complete construction on time.

Work with a scaffolding supplier who understands international construction. Whether you are building a bridge, a tunnel, or a power plant, we can provide an effective scaffolding solution.

📞 Welcome to contact our engineering team...

FAQ

1. What types of projects is the Ringlock system best suited for?

The Ringlock scaffolding system is ideal for large infrastructure projects such as bridges, tunnels, subway systems, oil and gas plants, power stations and prefabricated buildings. Its modular design allows for flexible adaptation to complex layouts and high-load construction needs.

2. How does Ringlock improve construction efficiency compared to traditional scaffolding systems?

Ringlock's bolt-free, tool-free locking mechanism speeds up assembly and disassembly, and is 30% more efficient than traditional pipe clamp or frame systems.

3. What is the typical delivery time for overseas orders?

Delivery time depends on the size of your order and the destination, Typically, production takes approximately 20-25 days, with an additional 1-2 months for sea freight. Due to the extended shipping duration, GETO can't offer emergency project support and container consolidation services.