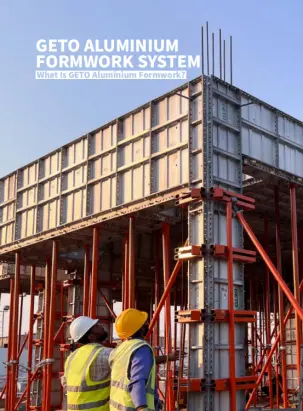

On construction sites, formwork not only shapes the structure but also plays a key role in determining the quality of concrete finishing. How do different formwork systems impact the surface appearance and construction efficiency? In 2025, with continuous advancements in building technology, GETO offers fresh insights and practical solutions. This article will take you through how various formworks influence both the look and integrity of concrete structures.

Why should we pay attention to the impact of different formwork on concrete forming results?

Paying attention to how different formworks affect concrete forming is important because the formwork directly influences both the structural quality and surface appearance of concrete. Different materials and designs impact the smoothness, density, and likelihood of defects in the finished concrete. Choosing the right formwork helps ensure construction accuracy, reduces issues like honeycombing or surface roughness, and cuts down on costly repairs and maintenance. Understanding these differences leads to stronger, more durable, and visually appealing buildings, while improving overall project quality and efficiency.

Special requirements for formwork systems in concrete engineering

Concrete construction requires special demands on the formwork system because it not only supports the weight of the concrete but also directly affects the structural safety and surface quality. The formwork must have enough strength and rigidity to prevent deformation during pouring, ensuring accurate dimensions and shapes. At the same time, it should be easy to install and remove to improve construction efficiency and reduce time and costs. Additionally, good sealing performance helps prevent leakage, resulting in a smooth and clean concrete surface. Choosing the right formwork system is essential to ensure quality and smooth progress in concrete projects.

Comparison of forming quality of aluminum formwork vs. wooden formwork vs. steel formwork

Aluminum, wood, and steel formworks each have their own strengths when it comes to concrete finishing quality. Aluminum formwork offers a smooth surface and stable dimensions, resulting in clean and attractive concrete finishes—perfect for projects that demand high-quality appearance. Wood formwork is more affordable but tends to absorb moisture and warp, which can cause dimensional inaccuracies and less consistent results. Steel formwork is strong and durable, ideal for repeated use, but its surface finish isn’t as smooth as aluminum and requires more upkeep. Choosing the right formwork depends on the project’s quality needs and budget—finding the right balance is key to the best outcome.

| Formwork Type | Surface Finish | Dimensional Stability | Durability | Maintenance | Cost | Typical Weight (kg/m²) | Reuse Times | Suitable Applications |

|---|---|---|---|---|---|---|---|---|

| Aluminum | Very smooth, high quality | Excellent, minimal deformation | High, corrosion resistant | Low, easy to clean | Medium to high | 8 - 12 | 50+ | High-end architectural projects, repeated use |

| Wood | Moderate, rough surface | Variable, prone to moisture and warping | Low, easily damaged | Medium to high, needs replacement | Low | 5 - 8 | 5-10 | Short-term projects, limited budget |

| Steel | Smooth but less refined than aluminum | Excellent, very rigid | Very high, impact resistant | Medium, requires rust protection | High | 12 - 20 | 100+ | Large-scale and repetitive industrial projects |

Analysis of the advantages of aluminum formwork on concrete forming quality

Smooth Surface for Better Finish

Aluminum formwork has a very smooth surface that creates clean, sharp edges, resulting in a visually appealing concrete finish and reducing the need for repairs.

Dimensional Stability, Less Deformation

Aluminum is strong yet lightweight, maintaining its shape well during pouring to ensure the concrete forms exactly as designed with minimal deformation.

Reduced Defects, Improved Quality

The stable formwork structure effectively reduces common defects like cracks and uneven surfaces, enhancing the overall quality of concrete forming.

High Construction Efficiency, Lower Human Error

Aluminum formwork is easy to install and dismantle, speeding up construction and minimizing quality issues caused by human mistakes.

Performance of aluminum formwork forming quality under high and low temperature environments

Aluminum formwork performs better than wood and steel in extreme temperatures. Its low thermal expansion keeps shapes stable in heat, while its good thermal conductivity helps concrete cool evenly in cold. Unlike wood, it won’t warp from moisture, and it’s lighter and easier to handle than steel. This makes aluminum formwork reliable for consistent quality and smoother construction in harsh conditions.

Changes in aluminum formwork quality over time

| Usage Times (times) | Formwork Type | Surface Finish | Dimensional Stability | Structural Strength | Deformation Rate | Maintenance Frequency | Remarks |

|---|---|---|---|---|---|---|---|

| 1-10 | Aluminum | Excellent | Excellent | High | Very Low | Low | New formwork, best performance |

| Wood | Average | Poor | Medium | Relatively High | Medium | Prone to moisture and deformation | |

| Steel | Good | Excellent | Very High | Low | Medium | Heavy, less flexible to use | |

| 11-20 | Aluminum | Good | Good | Relatively High | Slight | Low | Stable performance |

| Wood | Poor | Poor | Low | Relatively High | High | Significant wear, easy to damage | |

| Steel | Good | Excellent | High | Low | Medium | Requires rust protection | |

| 21-30 | Aluminum | Moderate | Fairly Good | Moderate | Moderate | Medium | Maintenance needed |

| Wood | Poor | Poor | Low | High | High | Mostly damaged | |

| Steel | Good | Good | Relatively High | Low | Medium | Performance remains good |

The role of aluminum formwork system in controlling the verticality of structures in high-rise buildings

How to achieve vertical ascent with “0 error” on each floor?

High-Precision CNC Machining

Aluminum formwork is typically manufactured using CNC machines, ensuring dimensional tolerances within millimeters or even smaller. This precision lays a solid foundation for controlling structural verticality.

Modular Design for Easy Assembly and Adjustment

The modular nature of aluminum formwork allows quick on-site assembly and fine adjustments, ensuring each floor’s formwork is accurately positioned to prevent cumulative errors.

Use of Laser Levels and Total Stations for Measurement

During construction, workers use laser levels and total stations to perform real-time checks on the formwork’s placement, quickly detecting and correcting any deviations.

Support Systems for Enhanced Stability

Specialized support and fixing systems are integrated with aluminum formwork to increase overall rigidity, preventing displacement or deformation during concrete pouring and ensuring vertical alignment.

Repeated Use with Stable Performance

With proper maintenance, aluminum formworks can be reused multiple times while maintaining consistent dimensions and performance, effectively reducing verticality deviations caused by formwork deformation.

Trained Teams and Strict Construction Protocols

Construction crews trained in aluminum formwork installation and verticality control follow strict protocols, ensuring each floor meets design requirements for vertical accuracy.

High-Rise Residential Building Project By GETO

GETO's advanced technology combined with aluminum formwork

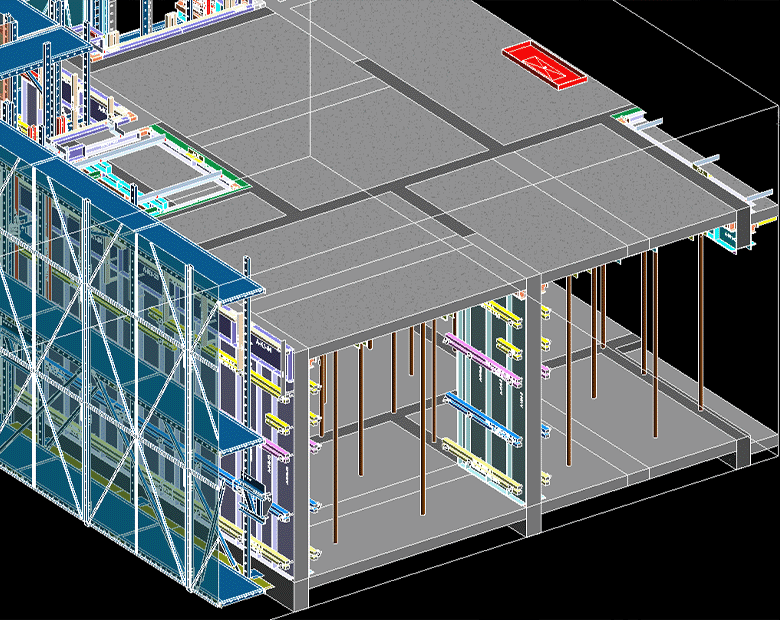

BIM+aluminum formwork, virtual construction simulation to predict forming errors in advance

GETO combines advanced BIM technology with high-precision aluminum formwork systems to create a virtual construction simulation platform that can predict and identify potential forming errors before concrete pouring. This innovative approach allows construction teams to precisely adjust formwork design and installation plans, avoiding rework and waste on-site caused by errors. Not only does this improve forming quality and construction efficiency, but it also showcases GETO’s leading role in promoting intelligent and digital transformation in the construction industry, giving clients confidence that every step of the process is under control.

GETO has independently developed the GETO-BIM automatic form adjustment software, which after three years of development has achieved 100% accuracy. This significantly improves the efficiency of aluminum formwork design, reduces errors, eliminates the need for factory pre-assembly, and speeds up on-site installation.

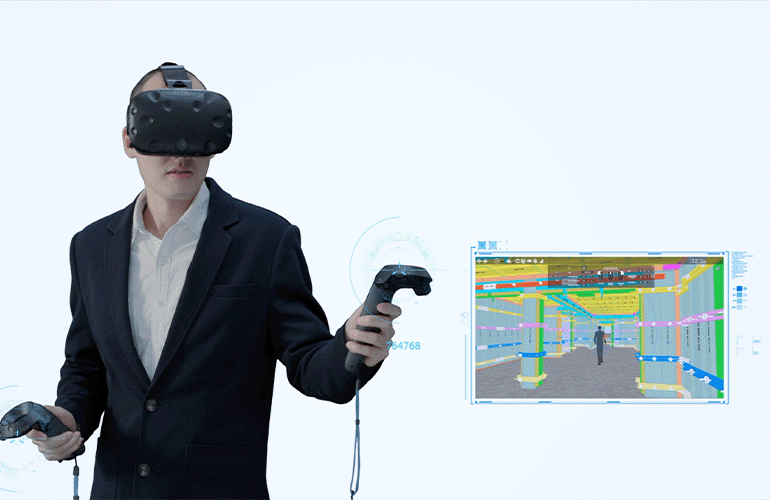

In addition, GETO has created the GETO-VR virtual reality inspection software, combined with specialized equipment, allowing clients to conduct 360° product inspections and on-site simulation experiences from home. This further enhances project visualization and collaboration efficiency.

Geto's intelligent formwork monitoring system plays a real-time control role in the forming quality of aluminum formwork construction

Geto’s intelligent formwork monitoring system continuously tracks key factors like alignment, pressure, and vibration during aluminum formwork construction. By providing real-time data and alerts, it allows the construction team to quickly identify and address any issues that might affect the forming quality. This proactive control helps prevent defects, reduces rework, and ensures that every pour meets strict standards for strength and finish. Ultimately, the system makes the entire building process smoother, safer, and more reliable.

Faq

Can the excellent forming quality of aluminum formwork reduce the cost of rework and subsequent repairs?

When aluminum formwork delivers excellent forming quality, it means fewer mistakes and defects during construction. This directly cuts down the need for costly rework and repairs later on. In other words, investing in high-quality aluminum formwork saves time, money, and stress by getting things right the first time.

Aluminum formwork requires high initial investment, but how can we obtain long-term returns by improving forming accuracy?

It’s true that aluminum formwork needs a higher upfront investment, but the key is how that cost pays off over time. By improving forming accuracy, you reduce mistakes, speed up construction, and cut down on costly repairs or delays. This means projects finish faster and with better quality, leading to savings on labor and materials. Over the long run, these benefits help you get a solid return on your initial investment and make aluminum formwork a smart, cost-effective choice.