1. Strategic Collaboration

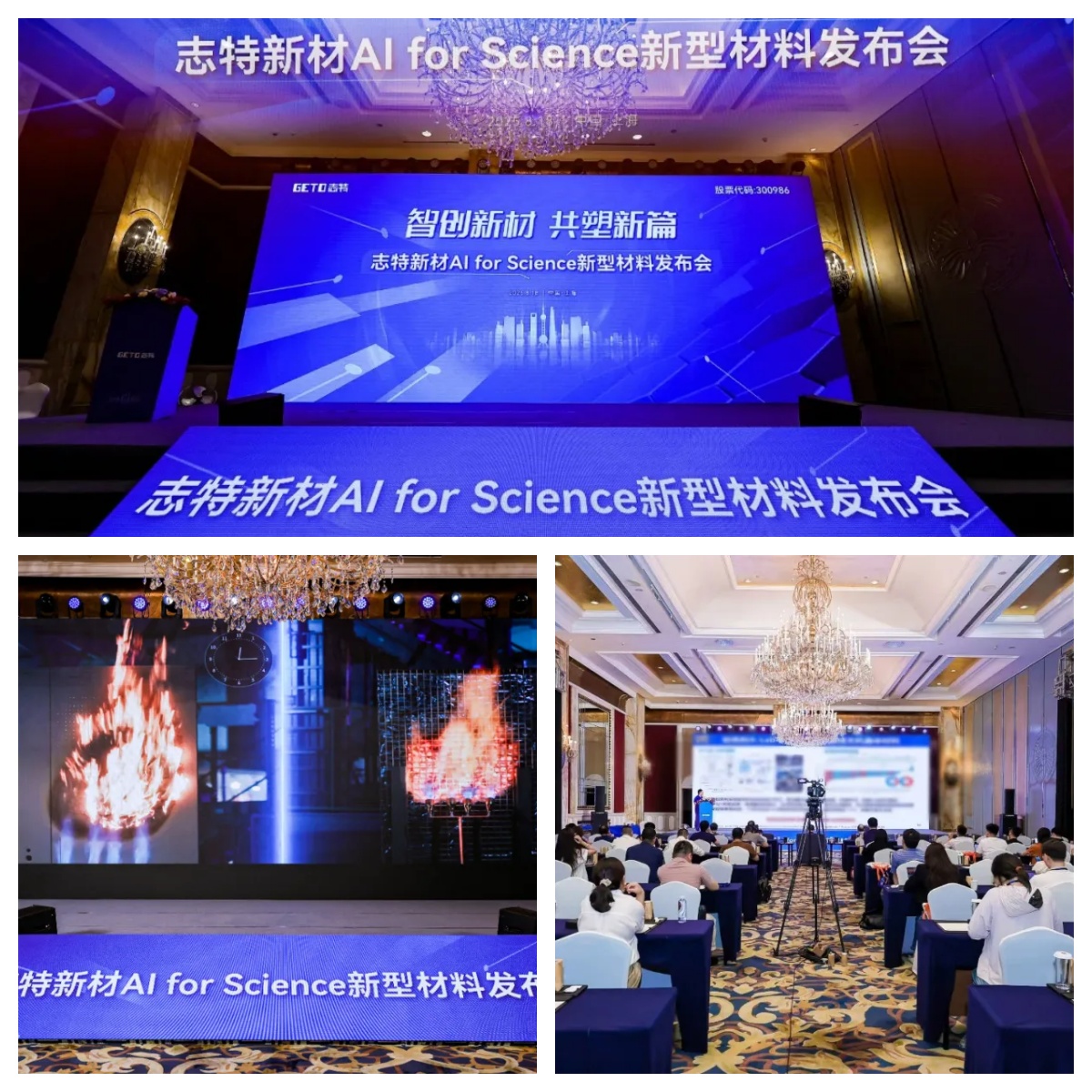

In Shanghai, GETO hosted the “AI for Science” New Material Launch Conference, inviting experts from universities, research institutions, and the industry to exchange insights. Overseas partner Francis Lloyd Chua, Chairman of Concrete Stone Corp, attended the event to witness the release of GETO’s latest innovations.

Meanwhile, GETO’s associated company Micro Era, in collaboration with East China University of Science and Technology, was selected as one of the “Top 10 Quantum Computing Application Scenarios in Shanghai.”

2. Technological Innovation

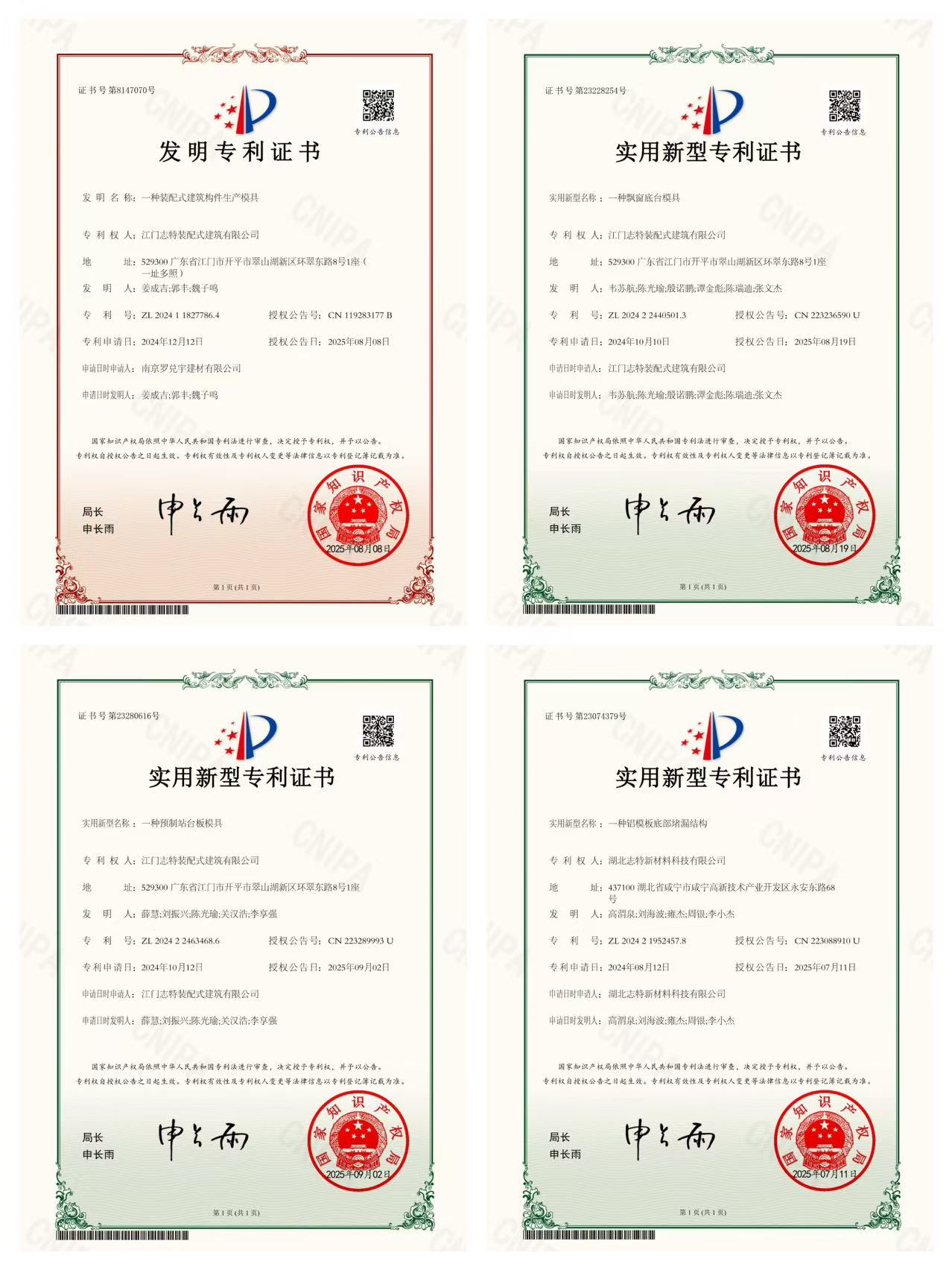

GETO obtained four new intellectual property rights, including one invention patent and three utility model patents.

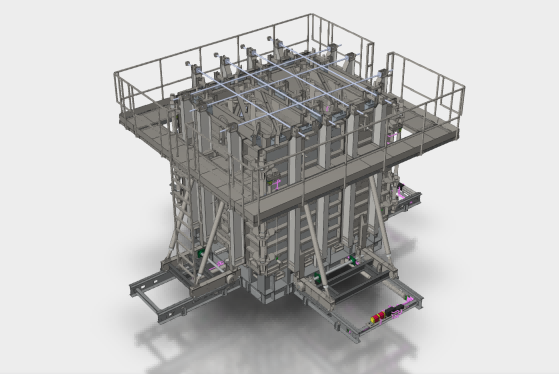

A new product — the Prefabricated Household Shelter (PHS) Molds— was successfully launched and applied on site. Combining functionality with aesthetics, it showcases meticulous design and superior craftsmanship. Featuring a modular structure, each component operates efficiently and independently while maintaining full system coordination. The design supports flexible customization to meet individual needs. Crafted from high-strength precision steel, it ensures exceptional dimensional accuracy and a smooth, refined finish through advanced processing techniques.

The Singapore PHS Mold is not only a robust fortress of precision-engineered steel, but also a symbol of safety and reliability — delivering superior performance and craftsmanship to ensure efficient production and protection.

3. Global Excellence

GETO showcased its products at several major international exhibitions, gaining strong customer recognition and reinforcing its global brand influence.

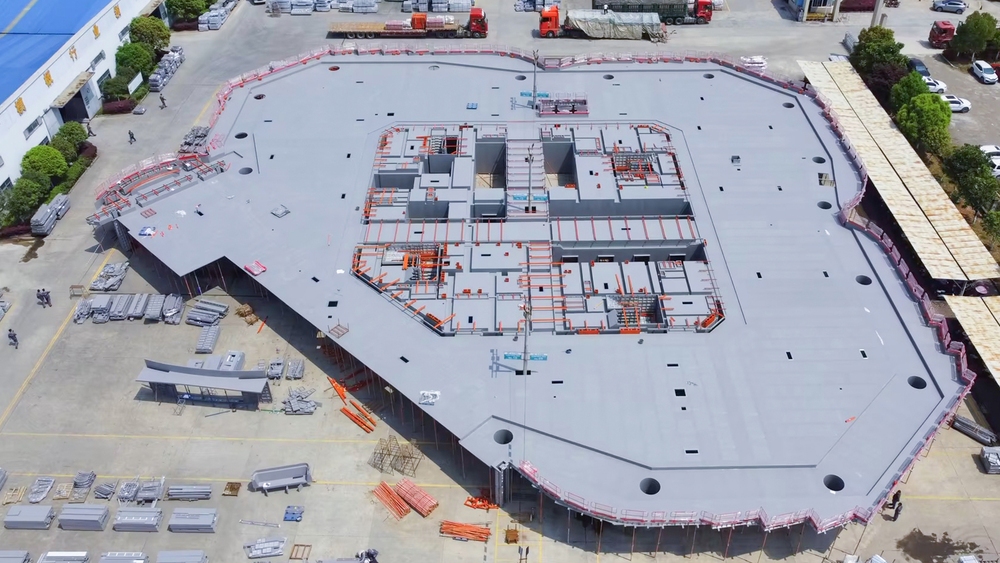

Middle East Steel Tunnel Formwork Project: Designed as an integrated system for modern engineering, the steel tunnel formwork combines high-quality forming and high-efficiency construction, breaking the limitations of traditional systems. Its robust steel components ensure structural precision and cost-effectiveness. With fast turnover cycles, it significantly reduces labor and construction time, enhancing overall project performance.

South Asia Commercial Complex Steel Formwork Project: The steel formwork system for horizontal structures achieved multiple goals — cost reduction, quality improvement, efficiency enhancement, and safety assurance. Its exceptional reusability delivers long-term economic benefits. When combined with the ringlock single-support system, it provides a solid safety guarantee. Compared with aluminium formwork, it offers the same high quality and safety with greater economic efficiency.

East Asia High-Rise Residential Project: This project adopted cantilever bracket formwork to meet building formwork needs. The system, lifted by tower cranes, allows simultaneous elevation of the formwork and brackets, ensuring fast, simple, and safe operation. With lower construction costs, it maintains high efficiency and strict cost control. Applicable to inner and outer walls, core shear walls, large columns, irregular columns, bridge piers, and silos, it provides a reliable formwork, support, and working platform solution for vertical concrete structures.

4. Awards & Honors

Recognized as a "Smart Factory" for outstanding achievements in digital transformation and intelligent manufacturing.

Became the first enterprise in the aluminium formwork industry to receive the Three-Star "China Green Building Material Product" Certification, recognizing its excellence in ESG (Environmental, Social, and Governance) practices.

Multiple projects across Southeast Asia received commendation letters from clients, demonstrating GETO’s high-quality products, reliable service, and commitment to integrity in project delivery.