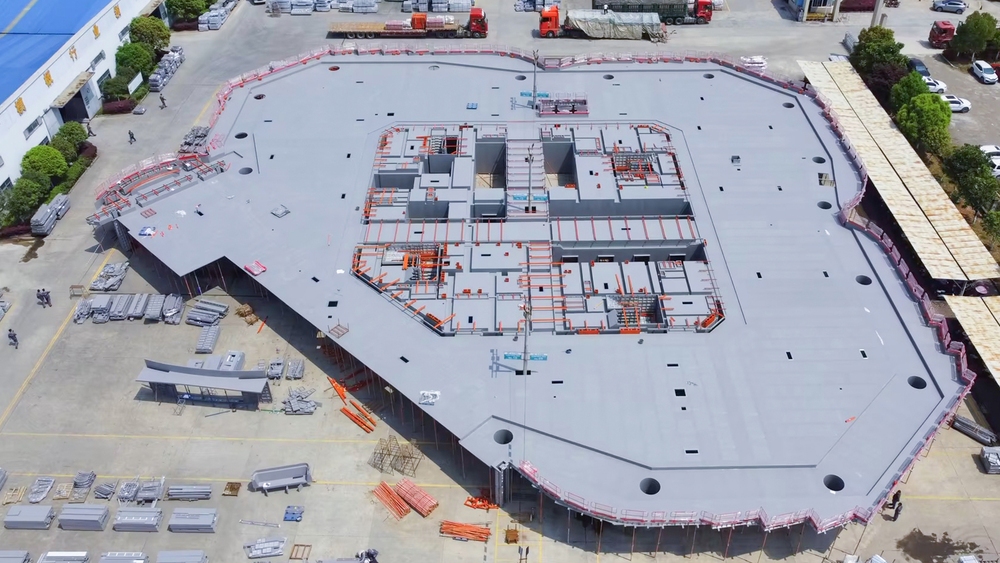

Located in the core area of a coastal gateway city in Southeast Asia, a landmark commercial complex—integrating a high-end hotel and diversified retail facilities—is rising rapidly. As the largest and most technically demanding commercial development in the region to date, this complex is set to become a new urban icon driving regional transformation. Spanning over 550,000 m², the development features high-rise towers, podiums, and basement structures. Given its complexity and scale, the project demands exceptional precision, adaptability, and construction efficiency—areas where GETO’s aluminium formwork system delivers solid value.

Smart Response to Varying Floor Heights

With typical floors at 3.6 m and refuge floors at 4.2 m, the project required a system capable of adjusting seamlessly to multiple vertical dimensions. GETO’s modular aluminium formwork system, paired with flexible support components, ensured smooth construction under these conditions. The project deployed over 23,000 m² of formwork for its typical floor configuration, showcasing the system’s strong adaptability in large-scale developments.

Integrated Solutions for Structural Challenges

The project consists of twin towers separated by a 450 mm-wide expansion joint. Taking into account on-site construction conditions and operational efficiency, a hanging formwork solution was adopted at the expansion joint area—significantly enhancing both safety and efficiency on site. For multiple post-cast strip sections in the structure, several sets of formwork and support systems were deployed to ensure the concrete strength met design standards, achieving both construction safety and structural quality.

Precision Craftsmanship Meets Cost Efficiency

The overall structure of the project features an arc-shaped design. In response to project requirements, GETO adopted a "straight-for-curved" formwork assembly approach, using rectangular and custom-shaped panels with angular adjustments to precisely control the arc geometry—maintaining dimensional deviation within 3 to 4 mm. This solution not only ensured the intended architectural appearance but also significantly reduced the cost of custom panel fabrication, offering a construction approach that balances aesthetics and cost-efficiency.

Practical Strategies for Settlement and On-Site Efficiency

To address the complex site conditions involving significant settlement variation between floors, GETO collaborated with the project team to unify the formwork design reference. During construction, floor backfilling was used to eliminate elevation discrepancies, effectively reducing the need for material changes and simplifying on-site management.

For the many large-volume column structures, square-round clamps were applied for reinforcement. In areas with embedded steel sections, nuts were welded directly onto the steel and secured using tie rods and walers, meeting the project’s requirement to avoid penetrating the steel while ensuring structural strength and stability.

This project reflects GETO’s commitment to providing solution-driven, adaptable, and efficient formwork systems for high-standard commercial developments. As construction continues, GETO remains a trusted partner in shaping landmark projects across global markets—building smarter, faster, and better.