Formwork, also known as shuttering, is a temporary or permanent mold used to hold freshly poured concrete until it hardens and achieves sufficient strength. It provides the desired shape and structural support during the curing process. Different types of formwork—such as timber, steel, plastic, and aluminium—are commonly used depending on project requirements, budget, and construction speed.

When it comes to constructing buildings efficiently, the choice of formwork plays a crucial role in project timelines, costs, and overall quality. Among the various options available, aluminium formwork has gained popularity worldwide due to its durability, reusability, and speed. In this article, we’ll compare aluminium formwork systems with traditional construction methods, helping you determine which solution best suits your project.

What is Aluminium Formwork: Features & Applications

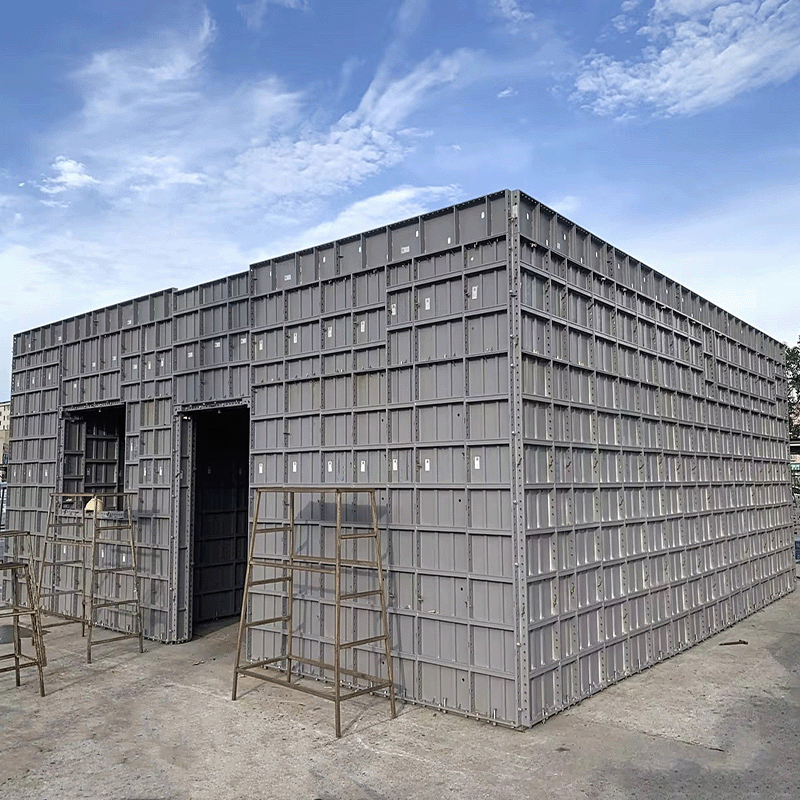

Aluminium formwork is a reusable formwork system made of lightweight, high-strength aluminium alloy. Designed for casting concrete walls, slabs, and columns, these systems provide a modular approach to construction. Each panel interlocks precisely with the others, creating a rigid and smooth mold for concrete.

The most economical application scenario of aluminium formwork: Suitable for projects with similar typical/standard floors and multiple stories, reusable up to 150-300 times (e.g., high-rise projects, townhouses, etc.). It’s also ideal for infrastructure projects that require speed, efficiency, high repeatability, and minimal material waste, such as utility tunnels and corridors, subway stations, etc.

Key features of aluminium formwork include:

- Lightweight yet strong: Aluminium panels are easy to handle on-site but can withstand high concrete pressure.

- Reusable panels: Panels can be reused up to 300 times, depending on maintenance.

- Precise dimensions: The system ensures consistent wall thickness and smooth finishes.

- Integrated system: Components like beams, panels, and props are designed to work together, reducing on-site adjustments.

Because of these advantages, the aluminium formwork system is particularly suitable for high-rise residential buildings, mass housing projects, commercial complexes, and other developments requiring fast construction cycles and consistent quality.

GETO Aluminium Formwork System

Traditional Formwork: Advantages & Challenges

Traditional formwork methods typically use materials like timber, plywood, or steel. These systems have been used for centuries and are generally handcrafted on-site, designed to be dismantled once the concrete sets. Each method comes with its own set of advantages and challenges:

Timber formwork: Timber remains a popular choice for small-scale projects due to its wide availability, flexibility, and ease of handling. It is cost-effective and easy to shape on-site, making it suitable for customized forms. Timber’s lifespan is limited, and it can absorb moisture, which may cause slight warping and affect surface consistency.

Plywood formwork: Plywood delivers smoother concrete surfaces and allows for some modular reuse. Its on-site adaptability makes it ideal for smaller projects or unique shapes. While heavier than timber and requiring proper maintenance to avoid wear, plywood remains a versatile and practical option for many construction needs.

Steel formwork: Steel is durable, strong, and designed for repeated use in demanding projects. Its rigidity ensures precise dimensions and smooth concrete surfaces, making it well-suited for large-scale and high-rise constructions. While heavier than some alternatives, steel formwork provides exceptional strength and stability, and is often used with cranes or specialized equipment for efficient handling.

While traditional methods may be accessible for small or simple projects, they generally demand more labor, longer construction time, and higher maintenance compared to modern systems like aluminium formwork.

Aluminium Formwork vs Traditional Methods: Key Factors

1. Durability & Lifespan

One of the most notable strengths of aluminium formwork is its durability. Made from a non-corrosive metal, aluminium can endure harsh weather and repeated use without losing its structural integrity. Panels can be reused 200–300 times, making them ideal for large-scale or multi-story projects where consistent quality is crucial.

Traditional materials like timber, while initially cost-effective, are prone to wear, warping, and decay, especially in humid conditions. Plywood usually lasts only 20–30 uses before replacement is necessary. Steel formwork offers better durability than timber but can rust over time and requires ongoing maintenance.

Aluminium formwork system provides long-lasting performance with minimal maintenance, outperforming traditional materials in lifespan and reliability.

2. Cost Considerations

At first glance, aluminium formwork comes with a higher initial investment compared to timber or plywood formwork. However, when considering its long-term reuse, it often becomes more economical. Large-scale projects benefit from reduced material replacement, lower labor costs, and fewer project delays, translating into significant savings over multiple construction cycles.

Timber and plywood formwork may be cheaper upfront, making them suitable for small or one-off projects, but frequent replacements can drive up total costs. Steel formwork sits between timber and aluminium in terms of cost, but is heavier and more expensive to transport and handle.

Aluminium formwork balances upfront cost with long-term savings, particularly for projects with repeated floor plans or extended timelines.

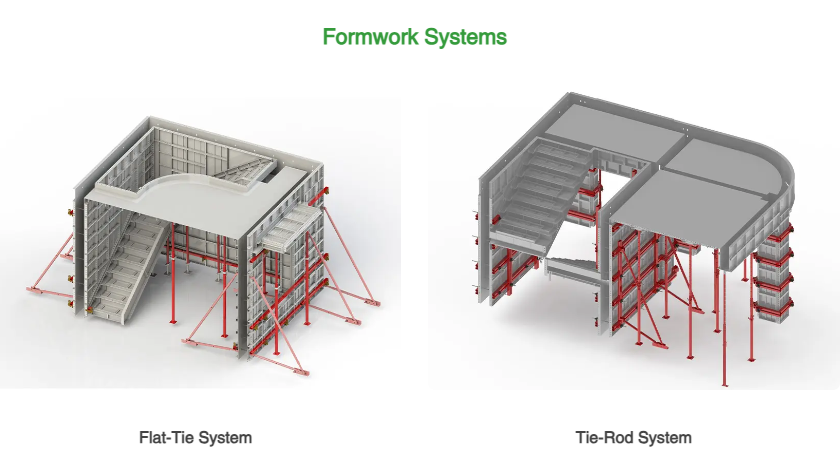

Aluminium Formwork Flat-Tie & Tie-Rod System

3. Speed & Efficiency

Aluminium formwork systems are pre-engineered for rapid assembly and disassembly. Panels interlock with precision, allowing construction teams to complete floors in as little as 3–5 days. This efficiency reduces labor needs and accelerates project timelines, which is particularly valuable for high-rise buildings or developments with repetitive layouts.

In contrast, traditional formwork demands more labor and time. Timber panels are usually custom-built on-site, requiring cutting, fitting, and alignment, which slows down construction. Steel formwork is quicker to assemble than timber, but it still cannot match aluminium formwork in speed, efficiency, and ease of handling.

Projects with tight schedules or repetitive designs benefit greatly from the speed and efficiency of aluminium formwork systems.

4. Design Flexibility

Aluminium formwork excels in modular projects with uniform designs. Pre-fabricated panels ensure consistency and precision but may require additional customization for unique architectural features, which can add cost and complexity.

Timber formwork is highly adaptable, making it the go-to choice for projects with curved walls, sloped surfaces, or unconventional geometries. Steel is somewhat flexible but still limited compared with timber when handling intricate shapes.

Aluminium formwork system works best for standard designs, while timber remains superior for creative or irregular structures.

GETO Aluminium Formwork for Villas

5. Environmental Impact

Sustainability is a strong point for aluminium formwork. Its high reusability reduces material waste, and at the end of its lifecycle, panels are 100% recyclable. This makes it a more eco-friendly choice compared with traditional materials.

- Refurbishment services, including design solutions and simple on-site panel maintenance guides, to maximize turnover.

- At the end of their service life, panels are either sold to other contractors or processed as high-value scrap aluminium, ensuring responsible and efficient material use.

Timber formwork and plywood panels have shorter lifespans, while steel formwork is heavier and requires more energy to manufacture. Aluminium formwork offers a sustainable alternative, with high reusability and efficient material use, supporting long-term environmental benefits.

6. Concrete Surface Quality

Aluminium formworks deliver smooth, consistent finishes on concrete walls. Precision engineering of the aluminium panels ensures uniform thickness, reducing the need for plastering or post-pouring surface treatments.

Timber and plywood can warp or become damaged, leading to rougher surfaces that require extra finishing work. Steel provides a reasonably smooth finish but often still demands minor touch-ups.

Aluminium formwork system ensures high-quality, visually appealing concrete surfaces with less labor.

Quick Check: Which Formwork Fits Your Project?

Use this guide to quickly see where aluminium or traditional formwork works best—from multi-story buildings to budget-conscious smaller projects.

|

Formwork Type |

Ideal Applications |

|

Aluminium Formwork |

- High-rise residential buildings |

|

Traditional Formwork |

- Smaller, one-off projects |

GETO: Your Formwork System Partner

At GETO, we provide a complete formwork system designed for global construction projects. From high-strength panels to adjustable supports, our solutions help contractors reduce time, cost, and labor while improving quality.

We also offer:

- Technical guidance for panel installation and project planning

- Customizable systems to match different building designs

- After-sales support for maintenance and lifecycle management

With GETO formwork systems, your construction projects become smoother, faster, and more reliable.

Conclusion

Choosing the right formwork system can make a significant difference in project outcomes. While traditional timber, plywood, or steel formwork may be suitable for small-scale or one-off projects, aluminium formwork systems provide advantages in speed, durability, precision, and long-term cost efficiency.

Investing in aluminium formwork ensures better quality, safer work conditions, and less environmental impact. For contractors seeking efficiency and consistent results, aluminium formwork is a solution worth considering.

Explore GETO aluminium formwork solutions today and bring a higher standard to your next construction project!