Metal formwork is a game-changer in modern construction. It's a crucial component, providing a mould for concrete structures.

Known for its strength and durability, metal formwork maintains its shape under heavy loads. This makes it a reliable choice for construction projects.

But the benefits don't stop at strength and durability. Custom metal formwork systems for large commercial projects are reusable and offer cost-effectiveness over time, making them a preferred choice for many construction professionals.

Moreover, they ensure a high-quality surface finish. This reduces the need for further plastering or treatment, saving time and resources.

As we approach 2025, the role of metal formwork in construction projects is set to become even more significant. This article will delve into its benefits, evolution, and future in the construction industry.

Stay tuned to learn why concrete metal formwork is an essential tool in modern construction.

Understanding Metal Formwork and Its Evolution

Metal formwork has been a part of the construction industry for decades. It began as a simple alternative to traditional wooden moulds, but it quickly gained popularity due to its superior features.

Initially, the adoption of concrete metal formwork systems focused on their reusability.

Over time, advancements led to the development of more versatile and sophisticated systems.

These systems can now accommodate complex architectural designs, including curves and intricate shapes. Today, metal formwork is integral to achieving efficient, high-quality construction across diverse projects. Its evolution continues as new technologies emerge, promising even greater benefits in the coming years.

Key Advantages of Metal Formwork for Concrete

Metal formwork offers numerous benefits for modern construction projects. These advantages range from enhanced project efficiency to improved structural quality.

One primary benefit is durability. Metal formwork withstands heavy loads and harsh weather conditions. This makes it ideal for demanding environments.

In addition, metal formwork is highly adaptable. It supports a variety of architectural styles with ease. This flexibility is crucial in modern construction.

Overall, metal formwork is an excellent choice for construction professionals. Its benefits lead to superior outcomes in both small and large-scale projects.

Key advantages of cost-effective metal Formwork include:

- Durability and Strength

- Efficiency and Time Savings

- Superior Quality and Finish

- Cost-Effectiveness Over Time

- Safety and Stability on Site

Durability and Strength

China metal formwork is known for its exceptional durability. Unlike wood, it does not warp or shrink over time.

The strength of metal formwork allows it to support heavy loads. This ensures structural integrity during the entire construction process.

Efficiency and Time Savings

Efficiency is a major advantage of metal formwork systems. These systems can be quickly assembled and disassembled.

Time savings in construction are significant. Quick assembly processes help meet tight deadlines without compromising quality.

Superior Quality and Finish

Metal formwork ensures a high-quality concrete finish. This reduces the need for additional surface treatments.

Concrete structures made with metal formwork often require less plastering. This results in smoother and more attractive surfaces.

Cost-Effectiveness Over Time

Initially, flexible metal formwork might cost more than wood. However, its reusability offers long-term savings.

Over the years, metal formwork's durability has led to reduced replacement costs. It's a wise investment for ongoing projects.

Safety and Stability on Site

Safety is crucial on construction sites. Temporary Metal Formwork provides stable and secure moulds, reducing risks.

Moreover, metal formwork systems can be equipped with additional safety features. These include guardrails and access platforms to protect workers.

Metal Formwork System Types and Their Uses

Metal Formwork for Buildings comes in various types, each suited for specific needs. The primary materials used are aluminium and steel.

These materials cater to different project scales and specifications. While steel is robust, aluminium offers ease of handling.

Steel formwork is preferred for heavy-duty applications. It provides remarkable support for large and high-rise structures.

Aluminium formwork, on the other hand, is lightweight and easier to transport. It is ideal for projects where speed and mobility are priorities.

Aluminium vs. Steel Formwork

The choice between aluminium and steel formwork depends on project requirements. Aluminium is favoured for its lightness and speed.

Its ease of use makes aluminium suitable for residential projects. However, it's not as robust as steel.

Steel, being extremely durable, is the go-to for large structures. It maintains its form under heavy loads, providing excellent support.

Both materials have their merits, and the choice often balances weight, strength, and cost considerations.

Customisation and Adaptability

Metal formwork systems offer significant customisation options. This adaptability ensures they meet unique project needs.

The modular nature of these systems allows for varied shapes and sizes. Architects can realise complex designs with ease.

Customisation is not limited to shapes. Metal formwork for concrete can integrate modern technologies.

This capability includes compatibility with Building Information Modelling (BIM) for enhanced precision. This ensures that metal formwork remains relevant in evolving construction landscapes.

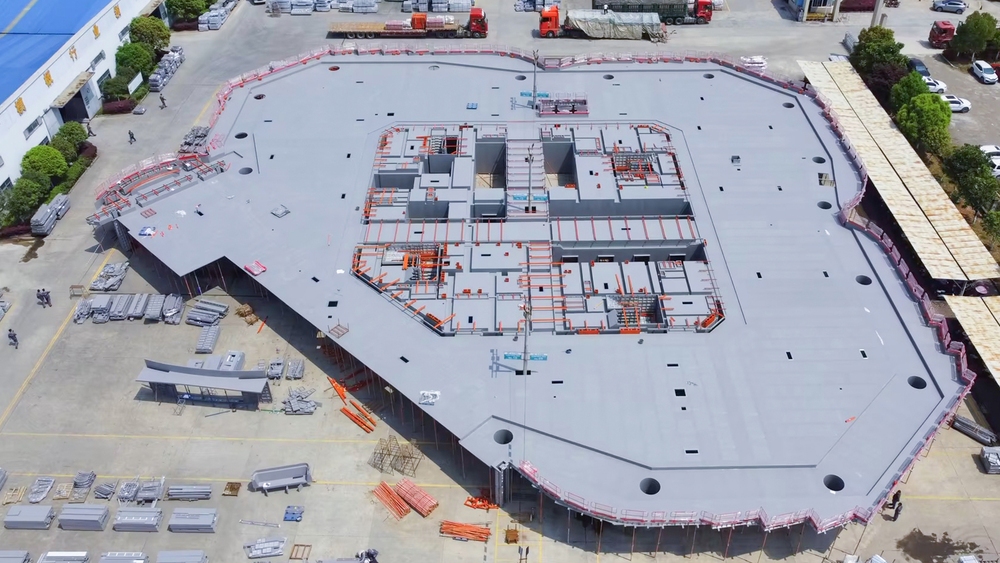

The Role of China in Metal Formwork Innovation

China is pivotal in the field of metal formwork innovation. The country's manufacturers lead the development of advanced formwork technologies.

Their competitive edge lies in offering cost-effective solutions without compromising on quality. This makes them a preferred choice globally.

China's expansive manufacturing capabilities allow for rapid production and distribution. This supports global construction demands.

Furthermore, Chinese companies often integrate cutting-edge technology, enhancing the efficiency and versatility of metal formwork systems. This innovation keeps China at the forefront of the formwork industry.

Environmental Impact and Sustainability

Metal Formwork for Foundations significantly contributes to sustainable construction practices. It reduces the need for timber, helping conserve forest resources.

Additionally, metal formwork systems are reusable, minimising construction waste. This aligns with global efforts to reduce the carbon footprint of projects.

The durability of metal formwork also means less frequent replacement, further supporting sustainability. It promotes longevity in construction materials.

Moreover, the precision of metal formwork reduces errors, decreasing the need for material-intensive corrections. This results in more efficient resource utilisation across projects.

Looking Ahead: Metal Formwork in 2025 and Beyond

As we approach 2025, metal formwork is set to revolutionise the construction industry further. Innovations are focusing on making these systems lighter and more efficient.

Integration with emerging technologies like robotics and 3d printing is on the rise. These advances will enhance precision, speed, and the overall construction process.

Moreover, the global push for sustainability will drive more widespread use of metal formwork. As environmental regulations tighten, the demand for eco-friendly construction methods will only grow.

Ultimately, Metal Formwork for Slabs is poised to play a critical role in modern construction's future. Its adaptability and efficiency will ensure it remains essential for years to come.

Conclusion: Why Metal Formwork is Essential for Future Construction

Metal formwork offers a blend of strength, efficiency, and sustainability. These attributes make it indispensable for contemporary construction projects. Its versatility and long-term cost benefits position it as the favoured choice.

As the industry evolves, metal formwork will continue to innovate alongside it. It supports the demand for safer and more sustainable building practices. Embracing Metal Formwork for Walls aligns with the construction industry's commitment to progress and quality. Its role in modernising construction methods will remain critical in the upcoming years.

Unveiling the Advantages of Steel Formwork: How China’s Metal Formwork Systems Boost Efficiency and Cost Savings

In the modern construction industry, choosing the right formwork system is crucial. The advantages of steel formwork make it the preferred choice for many large-scale projects. Steel formwork offers high strength and durability, ensuring precision and quality in structures while significantly improving construction efficiency. This stability and load-bearing capacity are especially vital in high-rise buildings and complex structures.

With the rapid development of China’s construction sector, innovations in the China metal formwork system have continuously pushed the industry forward. Metal formwork systems made in China are gaining global recognition for their advanced designs and strict quality control. Whether for highways, residential buildings, or industrial facilities, these systems provide flexible and efficient solutions tailored to various construction needs.

When considering project costs, cost efficiency and reusability formwork are among the top priorities for project managers. The high reusability of steel formwork drastically reduces overall construction expenses and minimizes material waste. Each set of formwork maintains excellent performance even after multiple uses, saving on procurement costs and shortening project timelines, thus enhancing overall project benefits.

In summary, steel formwork, supported by China’s advanced metal formwork systems, is becoming a driving force in promoting green and smart development within the construction industry thanks to its outstanding performance and economic advantages.