As of 2025, the Chinese scaffolding industry will remain a key force in the global construction supply chain, continuing to provide cost-effective and structurally reliable solutions for global construction projects. For construction contractors responsible for large projects, choosing a scaffolding supplier is not just about price, but also about construction safety, on-site efficiency and stability of later maintenance. Among the many competitors, there are only a handful of truly trustworthy companies.

This article will focus on introducing a Chinese scaffolding manufacturer that is widely recognized in the industry. With strong engineering strength, a complete international certification system and rich experience in overseas construction cooperation, the company has won long-term cooperation and praise from many contractors in China, the Middle East, Southeast Asia and other regions. If you are looking for a trustworthy partner, this will be a high-quality choice that you cannot ignore in 2025.

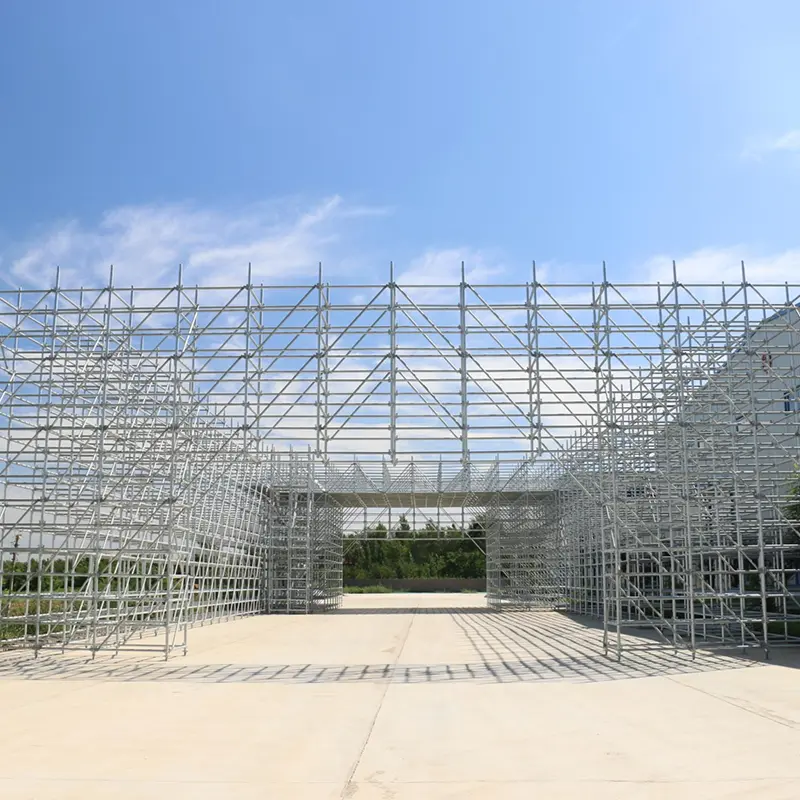

Ringlock Scaffolding System Manufacturer

GETO is a well-known scaffolding manufacturer in China and even in the world.

Company Introduction

Founded in 2011, GETO is a high-tech enterprise headquartered in Zhongshan, Guangdong, China, focusing on providing efficient, safe and green formwork system and scaffolding solutions for global construction projects. As an important promoter of China's construction industrialization, GETO integrates R&D, design, production and export, and has now developed into one of the brands with international influence in the industry.

GETO currently has 12 major production bases in China and overseas, and its products are exported to more than 60 countries and regions, covering Southeast Asia, the Middle East, Africa and South America. They are widely used in residential, commercial complexes, high-rise buildings and infrastructure projects. Its main products include aluminum alloy formwork systems, attached lifting scaffolding, steel structure supporting systems, etc., all of which have passed international quality and safety certifications such as ISO9001, ISO14001, ISO45001, and some products also meet EU CE and Singapore PSB standards.

Different from traditional scaffolding suppliers, GETO has significant advantages in digitalization and customization capabilities. The manufacturer independently developed the BIM automatic modeling system and 3D visualization construction platform to help contractors optimize solutions and pre-control risks in the early stages of the project, greatly improving construction efficiency and management accuracy.

As a listed company (Shenzhen Stock Exchange ChiNext: 300986), GETO adheres to the corporate culture of "integrity, respect, collaboration, and innovation" and is committed to becoming a long-term partner in the global formwork and scaffolding industry, and continues to create higher project value for customers.

Main product introduction

Aluminium Formwork Systems

GETO’s flagship product, widely used in residential buildings, apartments, and office towers. These systems are lightweight yet highly durable, reusable over 200 cycles, and designed for quick assembly—significantly reducing construction time and labor costs.

Self-Climbing Scaffolding

Ideal for high-rise exterior work, this system features self-climbing capabilities that rise in sync with the building structure. It integrates protection, construction, and transportation functions to enhance safety and operational efficiency.

Steel Components and Precast Elements

Includes standardized parts such as stair molds, balcony formwork, and guardrail supports. These components support prefabricated construction methods, enabling standardized parts production and streamlined onsite assembly.

BIM Modeling and Remote Construction Systems

GETO’s proprietary digital platform offers visualization, clash detection, and project progress monitoring tools. This digital solution helps contractors optimize workflows, improve control, and ensure precision throughout the construction process.

Contact Details

Phone:+86 760 88589004

Email:geto_market@geto.com.cn

WhatsApp:+86 13702787366

Address:21F, Building B, Zhongshan Harbor of IDEAS, No. 25 Gangyi Road, Zhongshan Torch Development Zone, Zhongshan, Guangdong, China

Website: https://www.getoformwork.com/

In-depth analysis of scaffolding: industry trends and prospects.

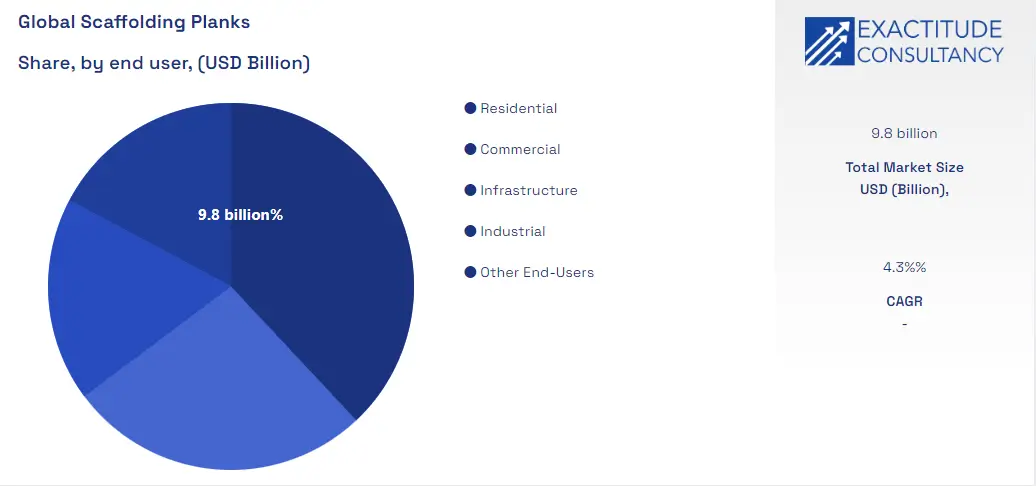

The global scaffolding market is witnessing a deep integration of traditional technologies with innovative applications. The Asia-Pacific region continues to lead, accounting for around 40% of the market share, driven largely by China’s massive market scale fueling rapid regional growth. Meanwhile, stricter safety standards and environmental regulations in Europe, the Middle East, and other regions are accelerating the industry’s shift toward smarter and greener solutions.

From conventional steel tube and coupler systems to IoT-enabled intelligent monitoring, the scaffolding industry faces dual challenges of technological innovation and price competition. The adoption of lightweight materials, real-time sensor monitoring systems, and the ongoing expansion of overseas infrastructure projects have become key growth drivers.

Looking ahead, companies that can seize opportunities in environmental sustainability and customized solutions will gain a competitive edge in the global high-altitude work platform market, valued at approximately $15 billion, enabling them to establish a strong multinational presence and sustain long-term growth.

Future Prospects

Market Segment Growth Potential

Aerial Work Platform (HAP) Replacement: In the field of high-rise building maintenance, HAP is gradually replacing traditional scaffolding due to its high efficiency and strong safety. It is estimated that the global HAP market size will reach US$15 billion in 2025.

Modularization and customization demand: The demand for customized scaffolding for special scenarios such as data centers and new energy (such as wind turbine tower maintenance) is increasing.

Overseas market expansion

Infrastructure demand is strong in Southeast Asia, the Middle East and other regions. Chinese scaffolding companies export production capacity through the "equipment + service" model to seize market share.

Accelerated industrial chain integration

Extension of rental services: Leading companies are transforming to integrated design, construction, operation and maintenance services to improve customer stickiness.

The rise of the second-hand trading market: The mature markets in Europe and the United States have formed a second-hand scaffolding circulation system, and China is expected to replicate this model.

Related articles

How to evaluate whether a scaffolding system is worth investing in?

Scaffolding Supplier

8 essential questions to ask before choosing a scaffolding supplier.

In the construction and industrial maintenance sectors, scaffolding is an essential piece of equipment. A high-quality scaffolding system not only affects construction efficiency and worker safety but also directly impacts long-term operational costs and return on investment. So, how can you determine whether a scaffolding system is worth investing in? Before committing to a supplier, make sure to ask these 8 critical questions.

1. Does the scaffolding system meet international and local safety certification standards?

Safety is the top priority for any project. Confirm whether the scaffolding system has passed certifications such as CE, ISO, ANSI, or EN12810/12811. For projects in China, check compliance with national or local safety inspection standards. Certifications indicate not only product quality but also legal compliance.

2. What is the durability and expected service life of the product?

Scaffolding is a long-term asset meant for repeated use. Inquire about the materials (aluminum alloy, steel, or composite), corrosion resistance, maximum load-bearing capacity, and performance in harsh environments (heat, humidity, strong winds). A system with a 10-year lifespan versus one that lasts only 3 years can mean tens of thousands of dollars in cost differences.

3. Is the scaffolding system modular and easy to assemble?

A top-tier system should feature modular design for fast assembly, disassembly, and expansion. Ask how long setup typically takes, how many workers are required, whether special tools are needed, and whether it supports various applications (bridges, factories, high-rises, etc.). This directly impacts labor costs and project timelines.

4. Is technical support and after-sales service available?

A reliable supplier will provide design consultation, on-site guidance, technical assistance during execution, and ongoing support such as maintenance advice and spare parts supply. Especially for teams unfamiliar with newer systems, training and emergency response capabilities are crucial.

5. Is the pricing structure transparent? Are there any hidden costs?

Don’t be misled by a low unit price. Clarify whether the quoted price includes taxes, shipping, installation, technical support, etc. Are there any additional rental, repair, or service fees? A transparent pricing structure helps you plan your budget accurately.

6. Are customer reviews and project case studies authentic and trustworthy?

Reputable suppliers will readily share past projects, client testimonials, and user feedback. Ask to see real construction photos, videos, or even visit a current project site. This will help you evaluate how the system performs in real-world conditions.

7. Does the supplier offer customized solutions?

Each project may have unique requirements for height, span, load capacity, or mobility. Check whether the supplier can tailor structural designs, component sizes, or surface finishes to your needs. This enhances efficiency and elevates your brand’s professional image.

8. Is the delivery timeline and supply capacity reliable?

Project schedules are often tight. Can the supplier maintain stable inventory? Are delivery lead times clear and guaranteed? Can they handle urgent or additional orders? Any delay in delivery can disrupt the entire construction timeline and cause a chain of losses.

Choosing a scaffolding system isn’t just about getting the lowest quote. You’re investing in a safe and efficient construction support solution. Before making a decision, asking these 8 questions is a professional, responsible approach—for your project, your team, and your financial investment.

Why choose GETO as your scaffolding supplier?

China Scaffolding Manufacturers

In a market full of options, GETO stands out as a trusted partner for scaffolding and formwork systems across global infrastructure and high-rise building projects. But what exactly makes GETO the preferred choice for contractors, developers, and engineers worldwide?

1. Proven Track Record Across Global Projects

GETO has successfully served over 50 countries, with projects ranging from residential towers to large-scale public infrastructure. From Southeast Asia to the Middle East and Latin America, GETO’s scaffolding solutions have been applied in some of the most demanding and high-standard construction environments. This international footprint is a strong testament to the company’s technical expertise and product reliability.

2. Comprehensive Product Range for Diverse Needs

GETO provides a full range of scaffolding systems, including:

Ringlock Scaffolding – modular, high-load capacity, suitable for complex structures

Cuplock Systems – robust and efficient for heavy-duty applications

Frame Scaffolding – ideal for residential and small-to-mid-size projects

Shoring & Formwork Systems – designed for concrete support and structural stability

Whether you’re dealing with curved facades, tall core walls, or suspended platforms, GETO offers tailored scaffolding solutions to meet your project's specific structural and spatial requirements.

3. Certified Safety and Compliance Standards

Safety isn’t just a promise—it’s a priority. All GETO products are manufactured under strict quality control systems and comply with international standards, including:

EN12810/12811

ISO9001:2015

CE Certifications

This guarantees not only the safety of your workers but also compliance with local construction regulations wherever your project is located.

4. In-House Engineering and Technical Support

GETO’s value goes far beyond supplying materials. The manufacturer offers full-cycle technical support, including:

Project-specific design and load calculation

3D modeling and installation plans

On-site assembly guidance and technical training

After-sales service and component replacement

This end-to-end support ensures that your team can deploy scaffolding faster, safer, and with fewer errors, which ultimately reduces downtime and cost.

5. Efficient Logistics and Reliable Delivery

With multiple manufacturing bases and regional warehouses, GETO has a well-established global logistics network. Products are delivered on time and in full, with smart packaging that reduces storage space and on-site handling. For fast-moving projects or phased deliveries, this operational efficiency is a major advantage.

6. Customization and Flexible Cooperation Models

Every project is unique. GETO offers customized design services, OEM production, and even rental and buy-back options depending on client needs. Whether you’re a general contractor, a subcontractor, or a project owner, you can find a flexible cooperation model that aligns with your business goals.

7. Cost-Effective Without Compromising Quality

GETO strikes the right balance between cost and performance. Through optimized design, durable materials, and reusable components, GETO scaffolding systems help maximize your return on investment. Long-term savings are realized not only through reduced maintenance and repair costs but also through faster project completion.

8. Commitment to Innovation and Sustainability

GETO invests heavily in R&D and intelligent manufacturing, integrating automation and eco-friendly practices into its production lines. This means you’re not only using modern, high-performance equipment but also partnering with a brand that prioritizes green construction and environmental responsibility.

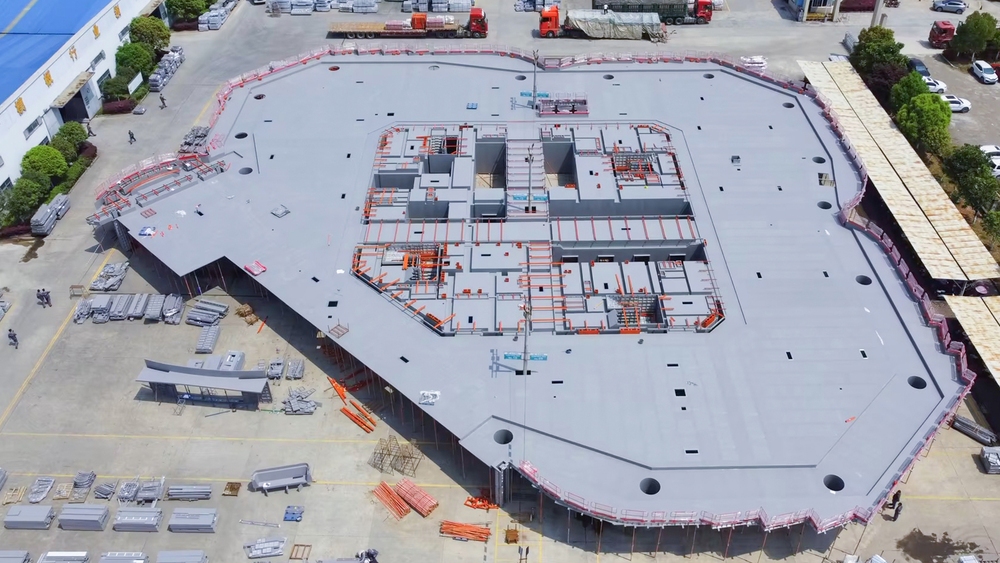

China Scaffolding Factory

Build Smarter, Safer, and Stronger with GETO

In today’s competitive construction landscape, every decision counts. Choosing GETO as your scaffolding supplier means choosing a partner who delivers more than just steel and components—it means choosing innovation, reliability, and world-class support.

If you're planning a new project or upgrading your existing systems, contact GETO today for a free consultation or customized proposal.

Successful application cases of GETO scaffolding system in actual projects

FAQ

Is GETO’s scaffolding system safe and certified?

GETO’s scaffolding systems are fully compliant with both domestic and international safety standards, including EN12810/12811, ISO9001, and CE certifications. Every product undergoes rigorous structural and safety performance testing before delivery. Our scaffolding features strong load-bearing capacity, anti-slip surfaces, and fall-prevention designs, making it ideal for high-risk construction sites. Certified test reports are provided with each batch, ensuring peace of mind throughout the construction process.

Can GETO’s scaffolding really help reduce construction time and labor costs?

GETO scaffolding is designed for modular, standardized assembly, using quick-lock systems that simplify installation and dismantling. This structure can increase work efficiency by 30%–50% compared to traditional systems, significantly lowering labor requirements. GETO also offers BIM modeling, construction plan optimization, and on-site technical guidance, helping your team save time from project planning to execution.

Can GETO handle simultaneous supply for multiple projects? What about after-sales support?

With large-scale intelligent manufacturing facilities and strong inventory reserves, GETO can support bulk orders and fast delivery, even during peak construction seasons. We offer 24/7 responsive after-sales service, including on-site technical training and customized engineering support. Whether you're managing a single site or multiple projects at once, GETO ensures reliable supply and consistent technical backing from start to finish.