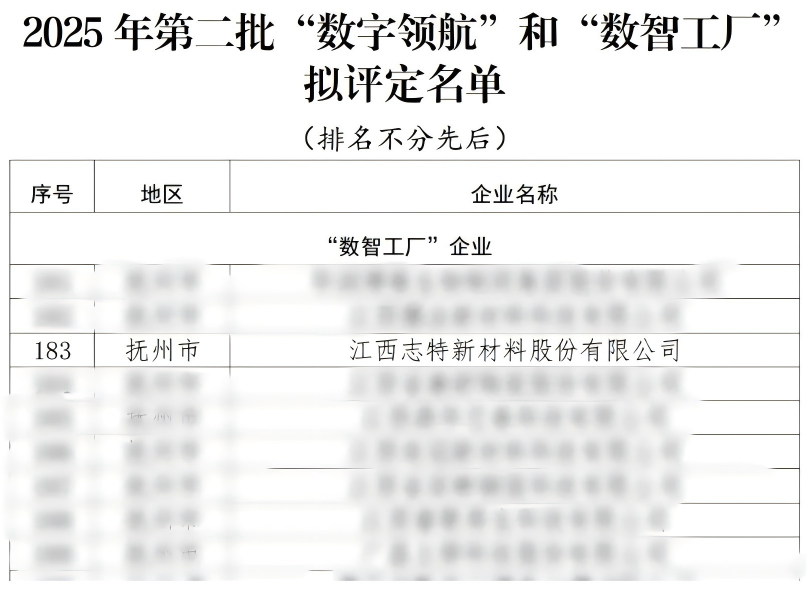

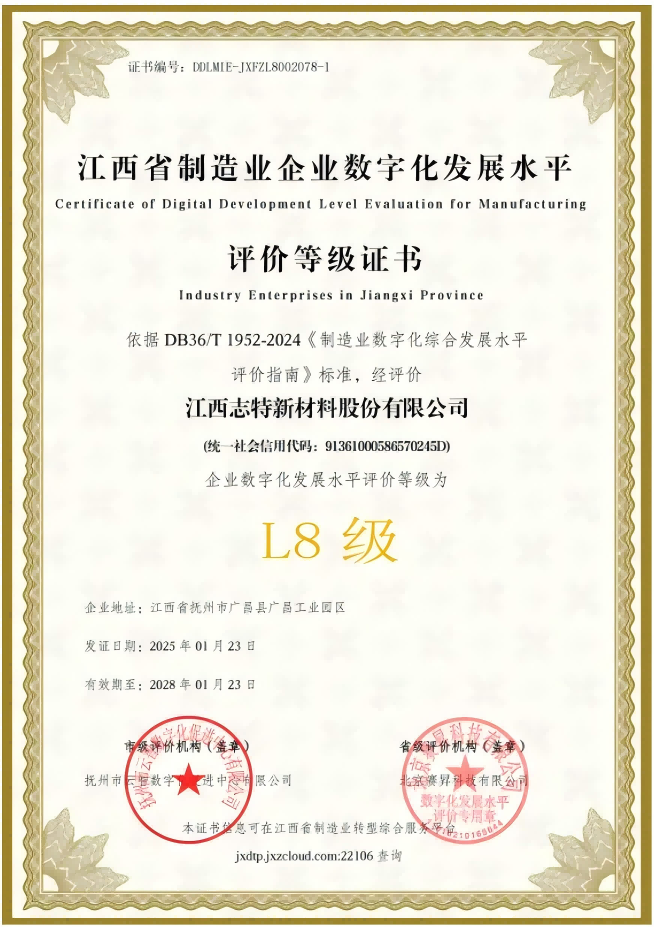

Recently, GETO (Stock Code: SZ 300986) was recognized as a “Smart Digital Factory” in Jiangxi Province, thanks to its deep practices and remarkable achievements in the field of digitalization. This honor comes as another significant provincial recognition following the company’s receipt of the “Digital Transformation L8 Benchmarking Award” in April this year. The award, organized by the Jiangxi Provincial Department of Industry and Information Technology, signifies that the company has reached an industry-leading level in dimensions such as intelligent manufacturing maturity and the integrated application of digital technologies.

Leveraging the strong foundation of a listed company and over a decade of industry experience, GETO drives the implementation of its digital transformation strategy through the dual engines of “Technology + Green Development.” The company has independently developed six core systems: the Industrial Digitalization “Executive Cockpit” decision-making platform, the “Digital Factory Real-Time Operation and Maintenance Management Platform,” the “End-to-End Information Management System,” the “Industrialized Design System,” the “VR Remote Acceptance System,” the “Material Coding and Scanning Management System,” and the “Intelligent Manufacturing System.” These systems have interconnected the data chains across the entire value chain, covering R&D and design, manufacturing, and supply chain management.

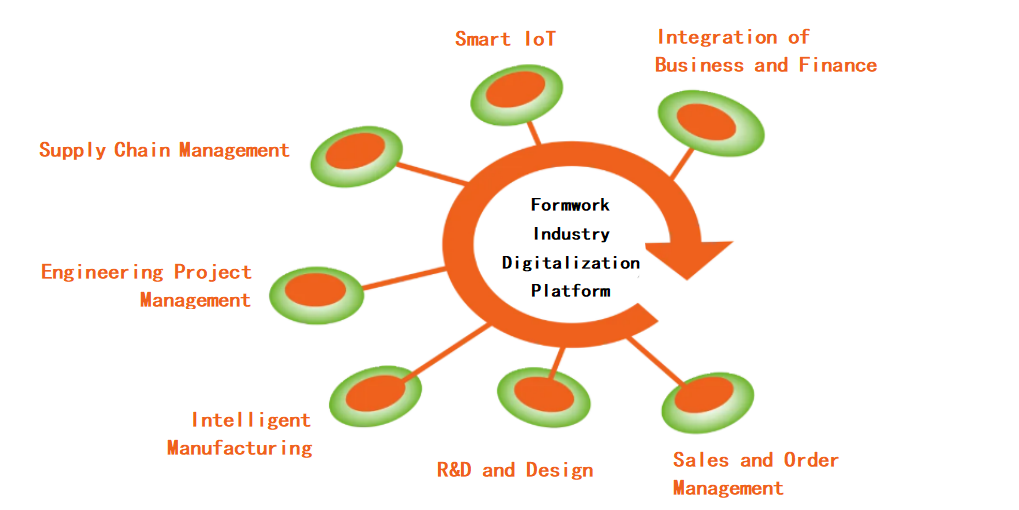

The “All-Scenario Digital Operation Management Platform for the Formwork Industry” developed by GETO is customer-centric and integrates the entire digital operation and management process covering pre-sales, in-sales, and after-sales services. It empowers enterprises to enhance their management capabilities across “Sales and Order Management – R&D and Design – Intelligent Manufacturing – Engineering Project Management – Supplier Management – Smart IoT – Integration of Business and Finance.”

Relying on the construction of the provincial-level Industrial Internet platform, the company has completed IoT transformation of its factory production lines and established a “cloud-edge-terminal” collaborative system. Through technological innovations such as predictive equipment maintenance and intelligent energy consumption monitoring, the company has already been recognized as a “Provincial Green Factory” and obtained certifications including “Carbon Footprint.”

Being awarded the title of “Smart Digital Factory” is both a milestone recognition of the effectiveness of our digital transformation strategy and a driving force for us to continue deepening digitalization. GETO consistently focuses on the deep integration of digitalization, informatization, and intelligence, achieving quality improvement, efficiency enhancement, and cost reduction through end-to-end data connectivity. By replacing traditional manual work with robotic operations and optimizing production processes, the company continuously strengthens its core competitiveness and sustainable operational capability. Looking ahead, we will continue to focus on the integration of “5G + Industrial Internet,” with priority given to building digital twin factories, developing innovative platforms such as intelligent supply chain hubs, and accelerating the upgrade from “manufacturing” to “smart manufacturing.” Through our practices, we aim to elevate the industry’s overall digitalization level and contribute more of GETO’s strength to driving high-quality development across the sector.