Amid the global green energy transition and infrastructure upgrade wave, GETO Formwork (Stock Code: SZ 300986) has become a core partner in complex engineering fields such as bridges, tunnels, utility tunnels, subways, airports, water conservancy projects, underground power station buildings, and so on.

Relying on the strong capabilities of the publicly listed company and over a decade of industry experience, GETO drives its business with a dual approach of "green construction + digital empowerment." It provides comprehensive, high-precision solutions for various large-scale infrastructure projects, with its technological reserves and engineering experience fully tailored to the construction demands of high-difficulty and complex working conditions.

Global Layout & Technological Strength: Building International Competitiveness

As a national high-tech enterprise and one of the Top 500 Chinese Listed Companies, GETO has already proven its comprehensive strength in the global market. Currently, GETO has established 12 major production bases worldwide, serving over 60 countries. The "GETO®" international trademark has been registered in 32 countries and regions. GETO has also obtained top international certifications, such as Malaysia’s CIDB G7 and Singapore’s BAND-2, making it the preferred partner for numerous multinational engineering projects.

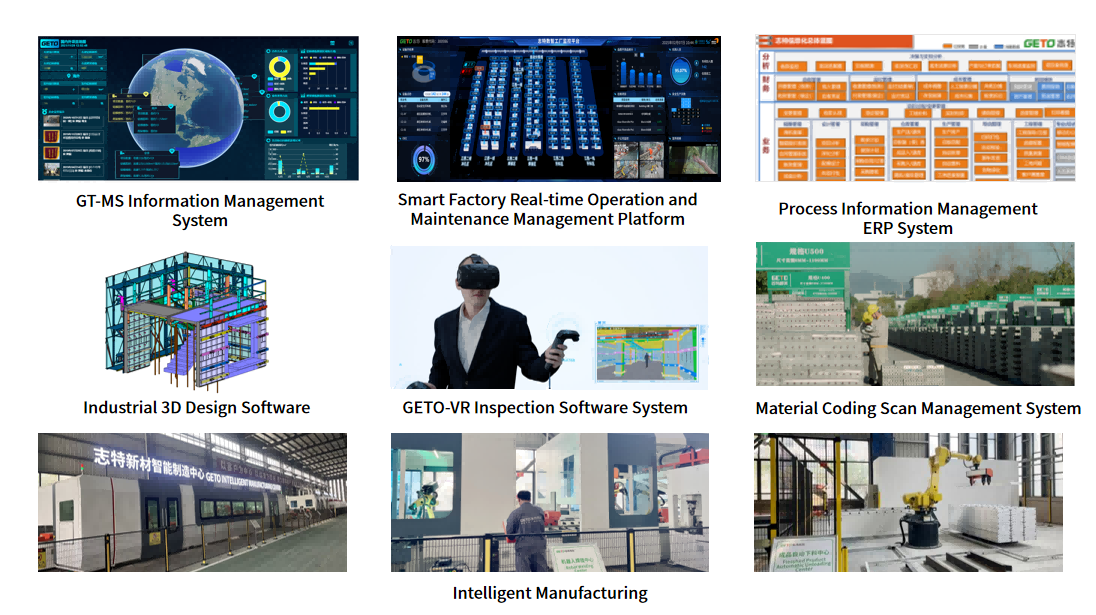

In the fields of technological innovation and digital transformation, GETO has become an industry benchmark. Its independently developed systems include:

- Smart Factory Real-time Operation and Maintenance Management Platform

- GT-MS Information Management System

- Process Information Management ERP System

- GETO Industrial 3D Design Software

- GETO-VR Inspection Software System

- Material Coding Scan Management System

- Intelligent Manufacturing

Together, these systems have established a complete intelligent management framework. GETO was honored with the industry’s first "Digital Transformation L8 Standardization Award," marking its leadership in integrating smart manufacturing with digital technology. Moreover, the "Carbon Footprint + Green Factory" certification, along with numerous other accolades, positions GETO as a leader in green construction and sustainable development.

Customized Solutions to Tackle Complex Engineering Challenges

Addressing the pain points of irregular structures and intricate working conditions in large-scale projects, GETO utilizes customized products and technological innovations to achieve "precise matching and efficient construction." The core advantages are reflected in three key dimensions:

- High-Precision Forming: Leveraging 3D modeling technology, GETO provides non-standard templates for irregular structures such as arched sluice gates and spillways, controlling concrete molding precision within ±2mm, effectively avoiding subsequent correction costs.

- Balance of Lightweight and Durability: By introducing new materials and innovative structures, GETO reduces the weight of templates by 15% compared to traditional steel templates, while special carbon steel treatment enhances corrosion resistance, significantly extending service life.

- High-Efficiency Adaptability: The modular, block-combination steel templates facilitate quick specification changes. Polished surfaces ensure smooth concrete finishes, easily adapting to various lining and construction scenarios.

These advantages have enabled GETO to develop a comprehensive solution system for scenarios including bridges, tunnels, utility corridors, subways, airports, water conservancy, power station underground plants, and more.

Bridge Engineering: Covering cast-in-place and precast full scenarios, including foundation caps, pier columns, and balanced cantilever carriage, ensuring the safety and efficiency of temporary facilities and excavation support.

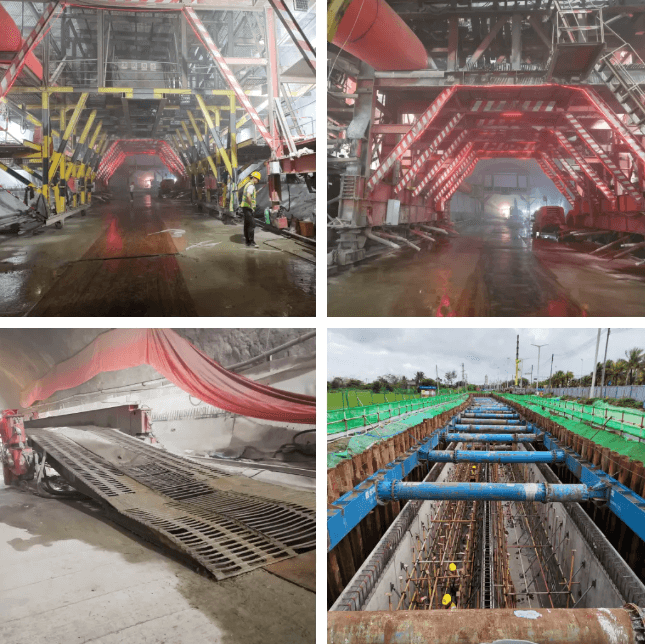

Tunnel Engineering: From fully automated intelligent hydraulic stack bridges, waterproof board trolleys, to TBM supporting formwork, achieving fully integrated smart construction processes, adaptable to complex projects such as shield tunnels and long-distance tunnels.

Metro Engineering: GETO shield tunnel lining products, supported by the self-developed shield tunnel lining prefabrication mold framework system, achieve standardized prefabrication. In addition, with a series of products such as the station main body intelligent mold framework system, and platform canopy mold framework, we work in unison to precisely match the prefabrication of tunnel lining, large-span high-altitude construction for stations, and canopy construction. This all-round support ensures the efficient progress of all aspects of metro engineering.

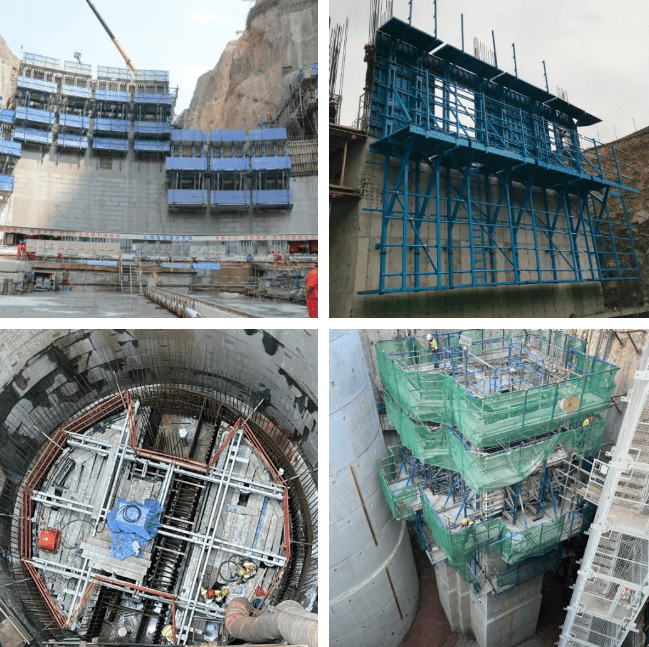

Water Conservancy Engineering: Systems such as automatic sloping climbing formwork for dams and automatic jacking formwork for shafts, precisely addressing the curved and high-altitude working requirements of structures like dams and spillways.

Power Plant Underground Workshop: Using industrial formwork, table formwork, and single-sided wall framework systems to meet the high-precision construction requirements of large-scale, complex plant structures.

Case Study: Engineering Experience in High-Difficulty Conditions

GETO's technical strength and solutions have been fully validated in numerous iconic and challenging global engineering projects:

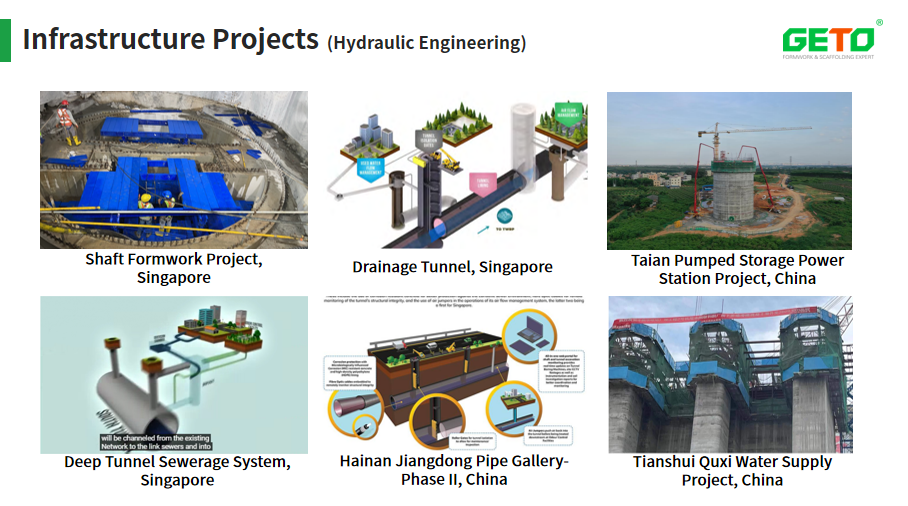

Water Conservancy Projects: Singapore’s deep tunnel sewerage system (underwater and deep-shaft engineering) and Hainan Jiangdong Utility Tunnel Phase II in China (complex utility tunnel structure) demonstrate GETO's technical capabilities in underwater engineering and high-drop structures.

Transportation Projects:

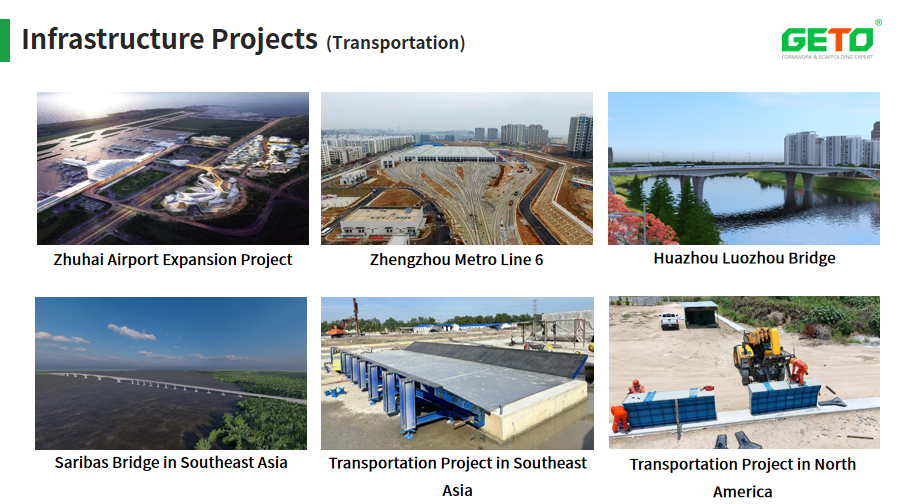

- China's Rangdaqu Bridge in Xizang and Malaysia’s Saribas Bridge (large span, marine environment) showcase GETO's capability to construct large-span bridges in complex maritime areas.

- China's Zhuhai Airport Expansion Project (construction without interrupting flights, space constraints), China's Zhengzhou Metro Line 6 (intensive multi-disciplinary coordination), and the North American Transportation Projects (high-standard regulations) reflect GETO's efficient and precise management of space limitations and multi-process coordination.

- The KUTS ART Smart Rail Project in Malaysia (construction in densely populated urban areas) further demonstrates precise control over space-restricted and multi-process coordination scenarios.

Industrial Parks: Southeast Asia factory, Shenzhen Shenfubao Ecological Technology Park, Shenzhen Chaoshen Jianshuo Technology Park, Shenzhen Minghu Smart Valley, Shenzhen Digital Manufacturing Center, Zhaoqing Medical Valley in China (large-scale factories with rapid construction, combining standardization and customization), meeting the high-efficiency and high-precision construction requirements of modern industrial facilities.

Steel Structure Projects:

- Malaysia Dairy Farm Project (large-scale agricultural facility), Malaysia-SKYLON Roof Steel Structure Hotel Project (irregular-shaped roof), showcasing GETO’s capabilities in long-span steel structure design and construction

- Shennan New Belle Industrial Park Parking Shed Project (public facility), Jiangmen Roof Steel Structure Project (industrial building) in China, demonstrating extensive experience in diversified steel structure applications.

Public Buildings: Nansha Civic Cultural and Sports Complex in Guangzhou (large-scale venue), Shenzhen Bay Cultural Plaza (irregular cultural space), Guangzhou Zhenbao Art Museum (precision in art space), Guiwan School in Shenzhen (educational infrastructure), Chongqing University Affiliated Hospital Science City Campus (complex medical architecture), and Maoming Island Art Center (special coastal environment) in China. These projects demonstrate the high standards and complex construction requirements of providing precise services for diverse public infrastructure.

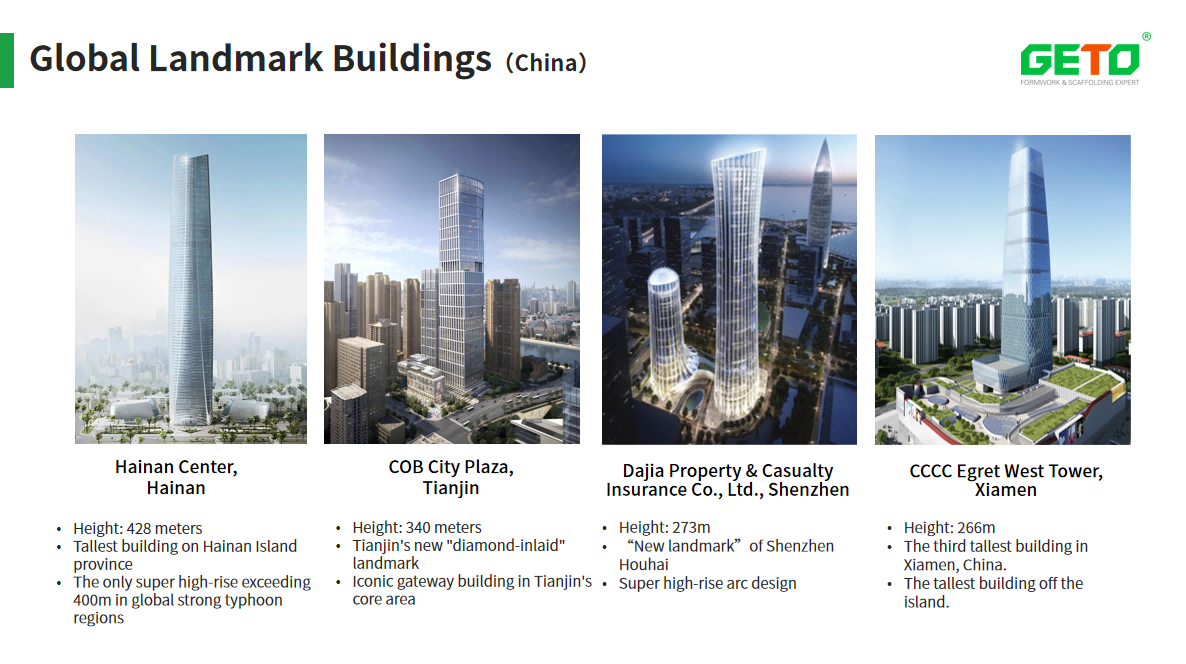

Landmark Buildings: International projects in North Africa, Southeast Asia, and South Asia conquer the challenges of super high-rise construction and adapt to the development needs of core market areas. Iconic skyscrapers such as Hainan Center, Tianjin City Plaza, and Shenzhen Dajia Insurance Headquarters continue to contribute to the upgrading of China’s urban skylines.

Final Word

Facing harsh conditions such as high altitudes, complex geology, and limited construction space, GETO’s digital management system and intelligent equipment enable remote monitoring and precise scheduling. Lightweight formwork and corrosion-resistant designs adapt to extreme environments, while modular block systems further enhance construction efficiency in confined spaces—these capabilities provide crucial support for innovative models in large-scale energy projects.

Backed by the strong foundation and brand influence of a listed company, along with years of global expansion experience, GETO possesses extensive market coverage and mature multinational operational capabilities. The company has established 12 major production bases worldwide, registered the “GETO®” international trademark in 32 countries and regions, and supplies products to more than 60 countries and regions across Southeast Asia, South Asia, the Middle East, Central Asia, the Far East, Africa, South America, North America, Europe, Australia, as well as the Chinese regions of Hong Kong SAR, Macao SAR and Taiwan.

Upholding the brand philosophy of “Be an Industry Benchmark, Create a World-Class Brand,” GETO consistently adheres to the high standards of making each project a “model benchmark project.” With “high-quality” products and services, the company provides comprehensive “1+N” green, innovative, and intelligent building system solutions, creating maximum value for its clients.