With accelerating global urbanization, the number of high-rise residential buildings, office towers, and mixed-use complexes continues to increase. High-rise building construction not only places extremely high demands on structural safety but also sets higher standards for the construction efficiency, load-bearing capacity, standardization, and turnover efficiency of formwork systems. How to select the most suitable formwork system from among different systems has become a crucial issue of common concern for construction contractors, developers, and engineering consultants.

This article will systematically analyze how to choose the best high-rise formwork/high-rise building formwork from five dimensions: the characteristics of high-rise building needs, key selection criteria, mainstream formwork system types, engineering cases, and supplier selection.

Why Must High-Rise Buildings Prioritize Systematized Formwork Systems?

High-rise buildings share the following characteristics: Numerous floors and high structural repetition: In high-rise residential buildings or apartments, standard floors are frequently repeated, and the turnover efficiency of the formwork system directly impacts the overall construction period.

High construction cycle pressure: High-rise projects commonly employ overlapping construction methods, therefore, an efficient formwork system can significantly reduce inter-floor cycles.

Higher safety risks: As the number of floors increases, the load-bearing capacity, wind resistance, and stability of the formwork system become particularly critical.

Limited tower crane resources: Some high-rise projects require reliance on automated climbing systems to improve construction continuity.

Therefore, the high-rise building sector generally adopts more systematic and higher-standard formwork systems. These systematic products achieve the best balance between safety, efficiency, and cost-effectiveness.

Six Core Criteria for Selecting a Formwork System for High-Rise Buildings

Regardless of whether steel formwork, Aluminium alloy formwork, or climbing formwork systems are used, a comprehensive evaluation should be conducted from the following six key dimensions:

Load-bearing capacity and structural stability:The formwork system must be able to withstand the self-weight of the concrete, construction loads, and vibration loads, ensuring no deformation or grout leakage.

Construction Efficiency and Turnover Speed: The faster the standard floors of a high-rise building are completed, the more controllable the overall project schedule becomes.

Safety and Climbing Capability: For critical high-rise structures such as core tubes and shear walls, highly stable suspended or climbing formwork must be used to ensure safety during high-altitude operations.

Cost and Turnover Rate: Formwork systems are not just a one-time investment; turnover rate determines long-term costs.

Compatibility with Project Structure: Different building structures (shear walls, frames, core tubes, etc.) require different formwork systems.

Supplier Engineering Capabilities: Choosing an experienced and service-orientedformwork system supplier can significantly reduce design deviations and construction risks.

Mainstream Formwork Systems Applicable to High-Rise Buildings

High-rise buildings demand more systematic, lightweight, and efficient formwork systems. Therefore, the following are the most commonly used systems in actual projects. This section provides a brief overview based on existing geto formwork products.

Aluminium Formwork System

Aluminium Formwork Applications

Aluminium formwork is mainly used to solve the formwork construction of the cast-in-place concrete structure in housing buildings, offering advantages such as shortening the construction period and eliminating the need for plastering. By using aluminium formwork, it is possible to complete the pouring construction of one floor in 3 to 5 days.

Aluminium formwork is a new generation of construction formwork after timber and steel formwork, Aluminium alloy profile is the main material and it is made into formwork through machining, welding, and other processes, which is suitable for concrete engineering. Aluminium shuttering can be assembled freely according to different structures and sizes. its design andapplication is the innovation of formwork technology.

Advantages:

- High standardization in design

- Excellent forming effect

- High safety

- Less comprehensive cost

Quick-Deck System

Quick-Deck System Applications

Quick Deck System is catered to construct beam-less and large-area deck structures, such as car porch and podium. Its quick installation and dismantling characteristics are realized by adjusting the height of the adjustable props below its quick deck formwork. It can realize the fastening installation procedure by manually moving up the adjustable props head to hold up the formwork parts, while dismantling the formwork only requires moving down the adjustable props.

Advantages

- Fast Construction

- Easy and Compatible

- Quick-release Prop Head

- High Quality

Single Side Wall Framework

Single Side Wall Framework Applications

The single-sided wall formwork system is designed for applications such as subway stations and basement exterior walls, where high waterproofing is required and the use of tie rods for reinforcement is not feasible. This system necessitates the erection of the formwork system on one side only during the pouring of concrete.

Advantages:

- Lightweight, can be manually moved or hoisted

- high material reusability rate

- lower material costs

- higher recycling value

- less manpower and safe

- meet environmental building requirements

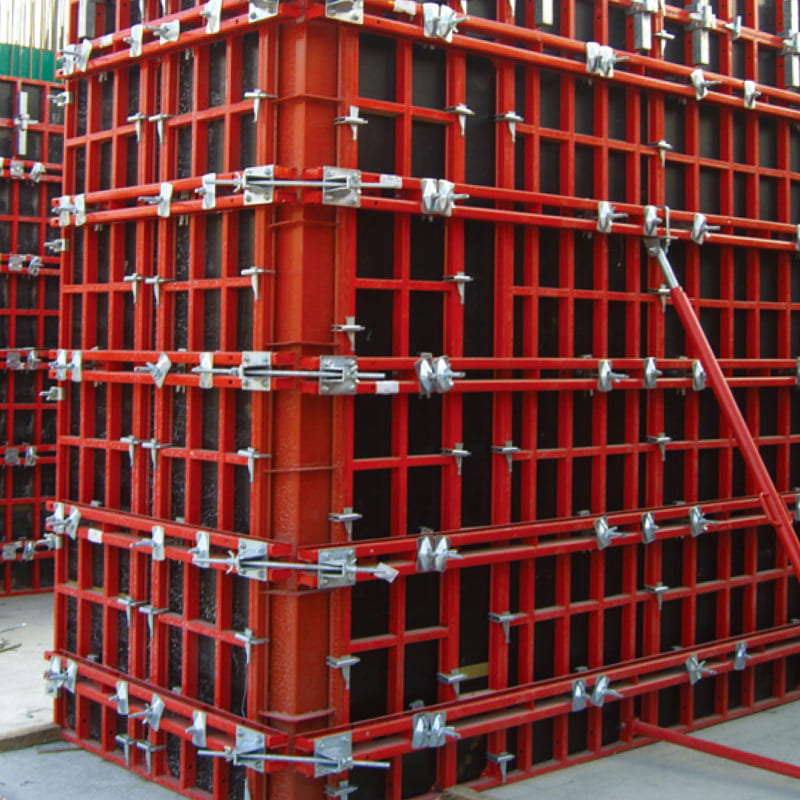

Steel-Framed Timber Formwork

Steel-Framed Timber Formwork Applications

Steel-framed Timber Formwork combines the casting effect of timber formwork with the strength of steel frames. It is a cost-effective alternative to aluminium formwork while achieving the same casting quality.

Advantages:

Heavy-Duty Formwork System

- Faster work efficiency

- Quick Assembly and Disassembly

- Seamless Connection and Efficient Hoisting

- Modular Design

- Durable and Low-Maintenance Panels

- High Load Capacity

- Thinner panel thickness, more suitable for structures with narrow internal spaces.

- Economical and Adaptable Column Formwork

Lightweight Formwork System

- High Efficiency

- High Quality

- Low Cost

- Safety

- Environmentally Friendly

Decision-Making Recommendations for High-Rise Building Formwork System Selection

Multiple architectural engineering studies indicate that the selection of a formwork system for high-rise buildings typically requires comprehensive consideration of structural type, project timeline, construction organization methods, and the supplier's engineering support capabilities. Based on common industry practices, the following three recommendations can be considered:

Select System Type Based on Structural

Repetition Research shows that in high-rise residential buildings with high repetition, Aluminium formwork systems often improve construction speed; while in special structural areas (such as transfer floors), hybrid systems with higher load-bearing capacity may be required.

Focus on Detailed Design and Construction Support Capabilities

The efficiency of a formwork system is not only affected by materials, but also by the quality of detailed design and the degree of component standardization. Therefore, when selecting a system, attention should be paid to the overall system solution, rather than just individual products.

Choose an Experienced formwork system Supplier with Technical Support

Due to the high risks and complexity of high-rise building construction, literature generally suggests that the supplier's engineering experience, project support services, and technical guidance will affect the actual performance of the system. Therefore, choosing a supplier with international project experience, a complete product portfolio, and the ability to provide technical support usually helps reduce uncertainty.

These suggestions can serve as preliminary references. The final selection of the formwork system still needs to be combined with specific project conditions and budget. Contact us to develop the best Formwork System for High-Rise Buildings for you.

Project Case: Aluminium Formwork Application in Southeast Asian High-Rise Commercial Complexes

GETO has extensive experience in high-rise building markets in various regions around the world. This case study, "Aluminium Formwork Practice for Commercial Complex: GETO Drives Efficient Construction in Southeast Asia," showcases the application of Aluminium formwork systems in complex commercial complexes, achieving:

- Intelligent response to varying floor heights

- Comprehensive solutions to structural challenges

- A perfect combination of superior craftsmanship and cost-effectiveness

- Practical strategies to improve installation and on-site efficiency

This type of case demonstrates that for high-rise building projects, choosing an experienced supplier (such as geto formwork) can effectively reduce on-site coordination and design risks.

How to Choose a Reliable Formwork System Supplier?

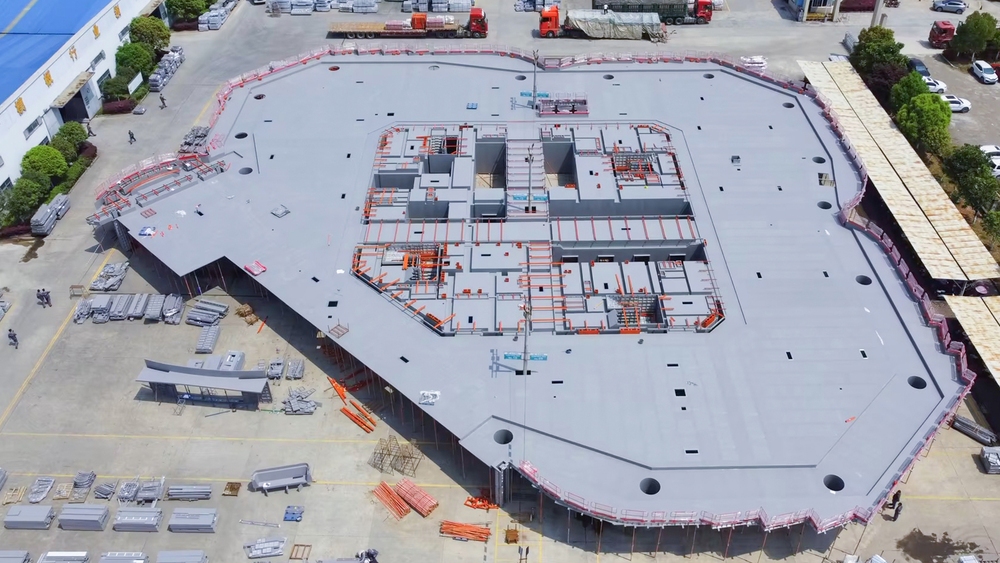

Reliable Formwork system Supplier

An excellent formwork system supplier must possess the following capabilities:

- Mature system solutions (not a single product, but a system-level product)

- Complete detailed design capabilities (details, assembly drawings, stress analysis)

- High-rise project experience (multiple regions, multiple building types)

- Factory capacity and global delivery capabilities

- Overseas engineering service teams

- A robust quality system and material certifications

The supplier's ability to provide complete high-rise formwork configuration solutions directly determines the success or failure of the project.

Conclusion: The Core Logic of High-Rise Building Formwork Selection

Choosing the optimal high-rise building formwork requires comprehensive consideration of safety, efficiency, cost, and adaptability. International engineering projects are increasingly favoring systematic, modular, and standardized formwork systems, and Geto formwork offers complete solutions in Aluminium formwork systems, tunnel formwork systems, quick-release systems, and steel-framed wooden formwork.

For contractors seeking shorter construction periods, higher quality, and lower rework rates, selecting a reliable formwork system supplier is crucial for project success. Contact us now for more information or a quote: geto_market@geto.com.cn