What is aluminum formwork system?

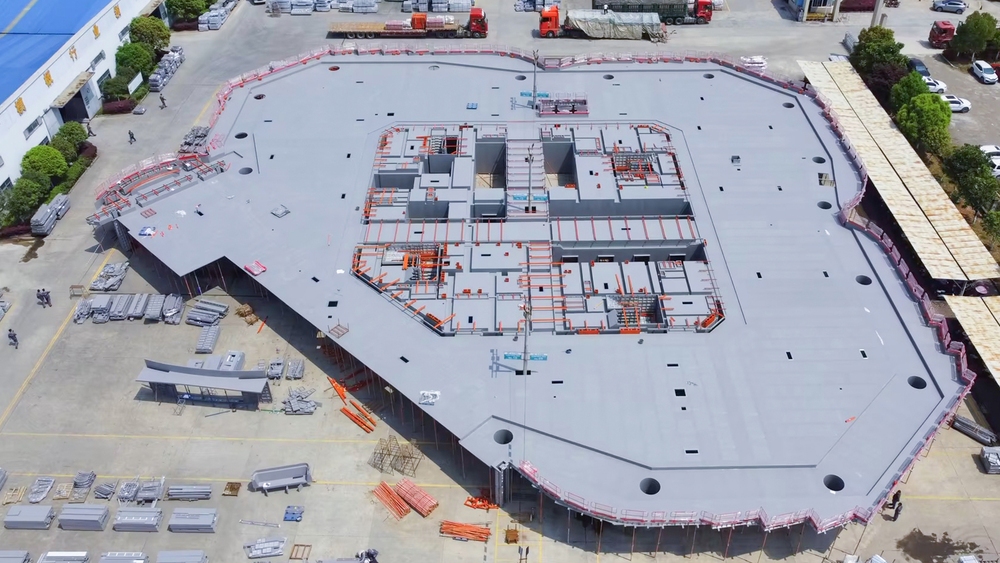

Aluminium formwork system is a new generation of construction formwork after timber and steel formwork. It consists of the template system, the support system, the reinforcement system and the accessory system.

Aluminium alloy profile is the main material which is made into formwork through machining, welding, and other processes. Aluminium formwork can be assembled freely according to different structures and sizes. Its design and application is the innovation of formwork technology.

Comparison of Aluminium Formwork & Steel Formwork & Timber Formwork

|

Characteristics |

Steel Formwork |

Timber Formwork |

Aluminium Formwork |

|

Material Performance |

|||

|

Average weight |

35-85kg/m² |

10.5kg/m² |

25-27kg/m² |

|

Loading capacity |

30-60kN/m² |

30kN/m² |

60kN/m² |

|

Tensile strength |

≥370MPa |

≥120MPa |

≥260MPa |

|

Characteristics of Installation Process |

|||

|

Installation difficulty |

Low |

High |

Lowest |

|

Labour intensity |

High |

High |

Low |

|

Security risk |

High |

High |

Low |

|

Depend on lifting machinery or not |

Need |

Need |

Needless |

|

Concrete Forming Effect |

|||

|

Concrete surface quality |

Rough,clean |

Rough |

Glossy,smooth |

|

Need to plaster or not |

Needless |

Need |

Needless |

|

Precision |

High |

Low |

High |

|

Comparison of Cost |

|||

|

Amortization cost |

High |

High |

Low |

|

Scrap value |

Middle |

None |

None |

|

Environmental Protection |

|||

|

Environmentally friendly |

Yes |

No |

Yes |

|

Generate construction waste or not |

None |

Much |

None |

|

Common formwork |

30-40 times |

3-5 times |

150-300 times |

|

Efficiency |

|||

|

Efficiency |

8-10 days/Floor |

10-12 days/Floor |

4-6 days/Floor |

*The data above are from GETO’s construction experience.

Aluminium Formwork Advantages

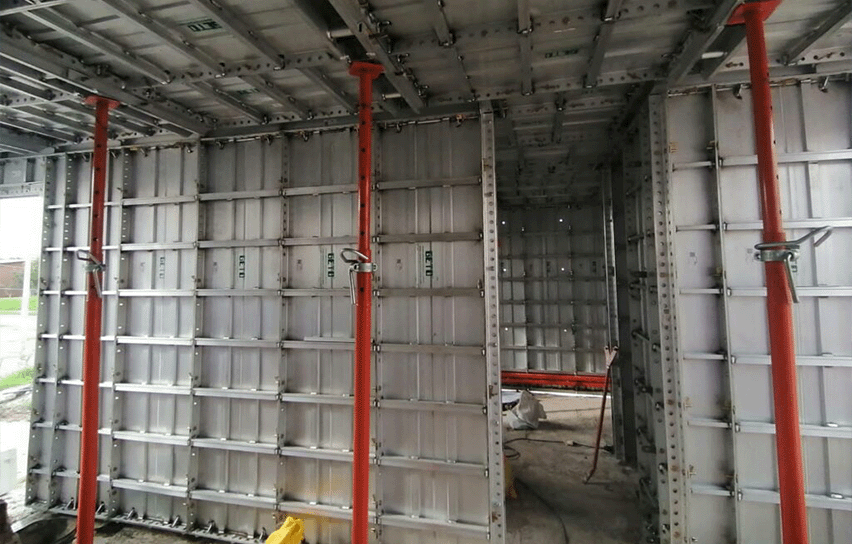

Excellent Forming Effect

- Large areas of single panels, less patchwork;

- High precision;

- High bearing capacity;

- High quality. It is easy to reach the quality standards of fair-faced concrete construction that require no plastering.

Safety

- The material of aluminium formwork has the characteristics of high strength, high bearing capacity, and not easy to deform;

- After the system is assembled, a whole frame is formed with high stability;

- No need of cranes or aerial work, decreasing the risk of falling accidents.

Speed

- Workers can carry and assemble the formwork efficiently without any equipment due to the light weight aluminium formwork;

- The assembly is simple and flexible like building blocks.

Less Construction Cost

- Reduce the integrated costs with high utilization;

- Save labor costs due to the high erection speed;

- Reduce heavy equipment leasing expenses such as crane;

- Reduce the cost of plastering and save the cost of decoration;

- The recovery value is high.

Environment Friendly

- The service life of aluminium formwork can reach 200-300 times, the utilization is high;

- The scrap aluminium formwork can be recycled, contributing to environmental protection;

- Reduce the construction waste.

GETO aluminium formwork

GETO has specializd in the aluminium formwork industry since 2011. So we has accumulated a lot of experience of construction method when used aluminium formwork. Please feel free to contact us to consulting and get the geto formwork price list. Click the link to know more about geto aluminium formwork: