Constructing a commercial complex involves complex planning, precise engineering, and reliable construction equipment. Among these, a high-quality scaffolding system plays a critical role in ensuring safety, efficiency, and structural accuracy. The ringlock scaffolding system has emerged as a preferred choice for many contractors and construction companies worldwide, offering versatility, durability, and ease of assembly.

What Is The Ringlock Scaffolding System?

The ringlock scaffolding system, known for its versatility and ease of assembly, is a modular scaffolding solution. It uses a unique rosette-type or ring connection at each joint, allowing horizontal and diagonal components to lock securely at multiple angles for quick vertical and horizontal alignment.

This modularity provides significant stability and flexibility for different construction scenarios, and it enables construction teams to adjust the scaffolding layout according to the building’s requirements without compromising structural integrity.

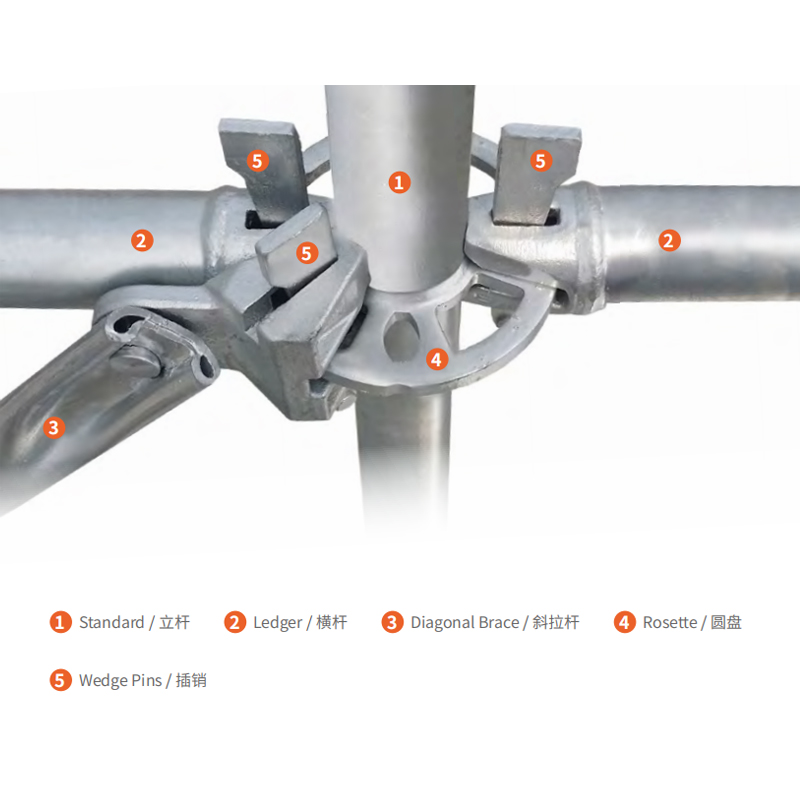

Unlike traditional scaffolding, which relies on fixed couplers, the ringlock system simplifies assembly, reduces labor costs, and accommodates complex architectural structures. Its components include:

- Standards (vertical posts): Provide the main load-bearing capacity.

- Ledgers (horizontal beams): Connect the standards and create the working platform.

- Rosettes (nodes): Facilitate multiple connection points for flexible configuration.

- Diagonal braces: Enhance stability and resist lateral forces.

- Base plates and steel decks: Ensure uniform load distribution and a safe working surface.

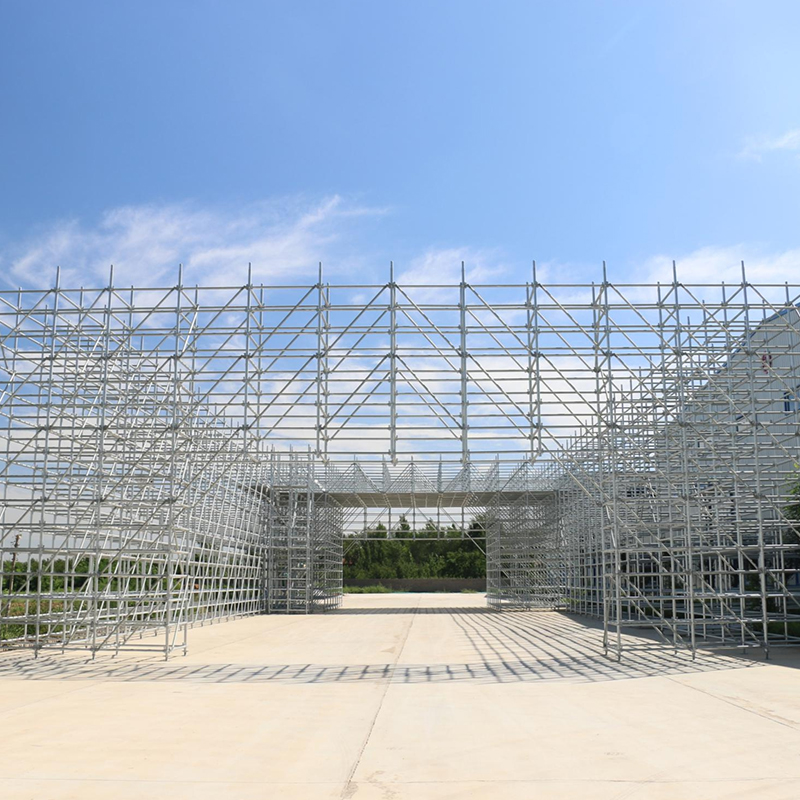

This modular design allows construction professionals to create scaffolding structures of various heights and configurations, suitable for commercial complexes, high-rise buildings, and industrial facilities.

Ringlock Scaffolding System

Advantages of Ringlock Scaffolding for Commercial Projects

1. High Load Capacity

Commercial buildings often require scaffolding that can support heavy materials, equipment, and construction crews. Ringlock scaffolding provides excellent load-bearing capacity due to its robust steel construction and interconnected design. This makes it suitable for multi-story structures where safety cannot be compromised.

2. Flexible Configurations

The unique rosette joint allows components to connect at multiple angles. This flexibility enables scaffolding to be customized to irregular building shapes, cantilevered sections, and large floor spans. It is particularly useful in commercial complexes with atriums, balconies, and complex facades.

3. Fast Assembly and Disassembly

The ringlock system minimizes time on-site thanks to its modular design. Each component easily locks into place without specialized tools, reducing labor requirements and overall project duration. For large-scale commercial projects, this efficiency translates into substantial cost savings.

4. Enhanced Safety

Safety is critical in commercial construction. The ringlock scaffolding system provides superior stability and secure connections, reducing the risk of accidents. Additionally, its vertical and diagonal bracing ensures resistance against wind loads and uneven surfaces, protecting both workers and the structure.

5. Durability and Longevity

Made from high-quality steel, the ringlock scaffolding system resists corrosion and wear, even under harsh construction environments. Its long lifespan makes it a cost-effective investment, especially for contractors managing multiple projects over time.

Ringlock Scaffolding System Applications

Applications in Commercial Complex Construction

The ringlock scaffolding system is highly versatile, making it suitable for various stages of commercial complex construction:

- Structural Framework Support: Provides temporary support for beams, columns, and floors during concrete pouring.

- Facade Work: Ideal for curtain wall installation, cladding, painting, or maintenance on commercial buildings.

- Elevated Platforms: Facilitates access for mechanical, electrical, and plumbing (MEP) installations.

- Bridge and Canopy Construction: Supports extended spans and heavy loads efficiently.

Its adaptability allows contractors to scale the scaffolding vertically and horizontally to match construction needs without compromising safety.

Installation Tips for Optimal Performance

While the ringlock scaffolding system is designed for easy assembly, following best practices ensures maximum performance:

- Site Assessment: Inspect the ground and foundation where scaffolding will be installed to ensure stability.

- Component Inspection: Check for damaged or deformed standards, ledgers, and accessories before assembly.

- Correct Bracing: Install diagonal and horizontal braces at recommended intervals for structural integrity.

- Load Management: Adhere to the recommended load limits to avoid overloading the scaffolding system.

- Regular Maintenance: Inspect joints and connections regularly to ensure safety throughout the construction process.

Proper installation and maintenance are crucial for maintaining safety and maximizing the lifespan of the scaffolding system.

Modular Ringlock Scaffolding System

Why Global Contractors Choose Ringlock Scaffolding

Construction companies worldwide prefer the ringlock scaffolding system for commercial complexes because it addresses common challenges:

- Standardization: Pre-engineered components ensure uniformity, making planning and material management easier.

- Space Optimization: The compact design reduces storage requirements on congested construction sites.

- Cost Efficiency: Reduced labor, faster assembly, and reusability lower overall project costs.

- Compliance with Standards: Many ringlock systems comply with international safety and construction standards, ensuring regulatory approval for commercial projects.

GETO offers a range of ringlock scaffolding solutions suitable for global markets. Our products combine precision engineering with rigorous quality checks, providing reliable scaffolding systems that contractors trust for critical commercial projects.

GETO Ringlock Scaffolding Solutions

GETO offers a comprehensive range of ringlock scaffolding systems designed to meet the demands of diverse construction projects. Our systems are widely used in bridge and tunnel projects, factory buildings, elevated water towers, power plants, oil refineries, and other specialized industrial structures. They are also suitable for supporting crossing bridges, large storage racks, stage and background frames, and complex commercial construction projects.

Ringlock Scaffolding System Supplier

Our ringlock scaffolding systems include M48 and M60 standards, with lengths ranging from 500mm to 3000mm. The primary materials are high-quality steel 0355 and 0235, ensuring excellent strength and long-term durability.

- M48 Ringlock Scaffolding System: Suitable for civil construction projects and lighter loads, such as operating platforms and smaller-scale commercial structures.

- M60 Ringlock Scaffolding System: Designed for heavy-duty applications, including municipal engineering, rail transit beams, swivel bridges, and freight viaducts.

Key Advantages

Strong Load Capacity: The M60 scaffolding system can support up to 19 tons per pole, providing the strength needed for large-scale projects.

Safe and Durable: Hot-dip galvanizing protects against corrosion, extending the service life even in harsh construction environments.

Fast Assembly: The disc-type self-locking plug allows for quick, secure connections, improving construction efficiency and reducing labor costs.

Economical: Optimized steel consumption and lighter components lower transportation and handling expenses.

Components & Accessories

The ringlock scaffolding system consists of essential structural components such as standards, ledgers, diagonal braces, jack bases, and so on. And key accessories include rosettes, wedge pins, ledger heads, and diagonal heads, all engineered to enhance stability and safety on-site.

Components of GETO Ringlock Scaffolding System

Ringlock Scaffolding System Applications

- M48 Ringlock Scaffolding System: Ideal for civil construction projects and platforms with relatively small load requirements.

- M60 Ringlock Scaffolding System: Perfect for municipal engineering, rail transit beams, swivel bridges, freight viaducts, and other projects with high load demands.

By choosing GETO’s ringlock scaffolding systems, contractors gain access to durable, flexible, and efficient scaffolding solutions capable of handling a wide range of commercial and industrial construction needs worldwide.

Conclusion

For commercial complex construction, the ringlock scaffolding system offers unmatched flexibility, safety, and efficiency. Its modular design, high load capacity, and durability make it the preferred choice for contractors around the world. By investing in a reliable scaffolding system from GETO, construction companies can streamline operations, ensure worker safety, and achieve successful project outcomes.

Whether managing a multi-story office tower or an expansive shopping center, the ringlock scaffolding system provides the robust support that modern commercial construction demands. GETO’s expertise ensures that every scaffolding project meets the highest standards, delivering performance you can trust. If you want more information about the GETO scaffolding system, please feel free to contact us at geto_market@geto.com.cn.