In modern building projects, efficiency and precision are crucial for success. One of the most effective ways to achieve this in concrete construction is through the use of table formwork systems. These systems have become an essential part of slab construction, helping contractors build faster, safer, and more cost-effectively while maintaining high structural quality.

1. Understanding Table Formwork Systems

A table formwork system (also called slab table formwork or flying formwork) is a large, pre-assembled formwork unit used for constructing cast-in-place reinforced concrete floor slabs. Unlike traditional small-panel formwork that requires time-consuming assembly and dismantling at each level, a table formwork can be lifted and reused directly from one floor to another using cranes.

Typically composed of a supporting frame, joists, and a decking surface, table formwork allows for efficient slab pouring and high-quality surface finishes. The system is especially useful in repetitive floor structures, such as commercial buildings, hotels, and residential towers, where construction speed and consistency are key.

By reducing the need for repeated assembly, a table formwork for slab construction improves both labor productivity and material utilization, while ensuring accurate slab thickness and alignment.

Table Formwork For Slab Construction

2. Why Table Formwork Systems Are Popular in Modern Construction

The widespread adoption of table formwork systems stems from their strong advantages over conventional slab formwork methods.

Fast Construction Cycle

Since table formwork units are pre-assembled and reused across multiple floors, the construction cycle for cast-in-place reinforced concrete floor slabs is significantly shortened. Workers spend less time on-site adjusting and fitting individual panels, leading to faster project turnover.

High Reusability

Each table formwork unit can be reused many times, making it ideal for large-scale projects. The high material turnover rate contributes to lower long-term costs and more sustainable construction practices.

Safety and Stability

A well-designed table formwork system ensures excellent load-bearing capacity and structural stability during concrete pouring. Combined with guardrails and safe access platforms, the system provides a secure working environment even at elevated heights.

Improved Surface Quality

Because of the rigid structure and smooth formwork panels, slabs cast with table formwork typically have higher surface flatness and fewer finishing requirements.

Reduced Labor Costs

With simplified operations and minimal manual adjustment, fewer skilled workers are needed for installation and dismantling. This not only reduces labor expenses but also lowers the risk of errors on-site.

These benefits make table formwork for slab construction a preferred choice for developers and contractors aiming for productivity, safety, and quality in concrete projects.

Table Formwork For Slab Construction

How Table Formwork Enhances Slab Construction Efficiency

Efficiency is one of the main reasons why contractors are switching to table formwork systems. Unlike conventional high formwork setups that rely on numerous props and complex horizontal supports, table formwork is designed for mobility and repetition.

Each assembled unit can cover a large slab area, typically several square meters. After the concrete slab cures, the entire formwork unit can be lowered slightly, moved horizontally, and lifted to the next level by tower crane. This crane-handled mobility eliminates the need for complete dismantling and reassembly at each floor.

Additionally, the modular nature of the system allows for flexible adjustment according to building layout, making it adaptable to various slab thicknesses and heights. The result is a smoother workflow, fewer interruptions, and consistent quality across every level of the structure.

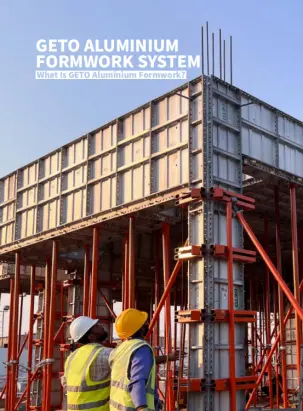

4. GETO Table Formwork System: Designed for High-Performance Construction

While many manufacturers offer table formwork, GETO’s truss-type table formwork system stands out for its innovation and practicality in real-world applications. Developed to overcome the limitations of conventional high formwork systems—such as complex operations and low efficiency—it introduces a new level of performance in slab construction.

Table Formwork System Supplier

Wide Application Range

The GETO table formwork system is suitable for pouring concrete thick slabs in projects with floor heights ranging from 3 meters to 4.8 meters. For higher floors, the system can be extended up to 8 meters by stacking trusses. It performs exceptionally well in large-span, deep-in, and column-cap-free cast-in-place slab structures without beams, where high efficiency is particularly important.

Key Product Features

Steel and Aluminium Alloy Profiles: Combining the strength of steel with the lightweight properties of aluminum, the system achieves an ideal balance between load-bearing capacity and manageable weight.

Large-Area, Full-Piece Transfer and Demoulding: The entire table formwork can be lifted and moved as a single unit, significantly improving assembly and disassembly speed.

Truss-Type Structural Design: Compared with single-layer truss systems, GETO’s truss-type design offers enhanced stability and flexibility. Adjustable connection methods allow the frame to be raised for higher slab pours while maintaining structural safety.

Core Advantages

- Safety: The system‘s stable truss structure and strong load-bearing capacity ensure a secure construction process, even under heavy concrete loads.

- High Efficiency: Fast installation and dismantling enable quick turnaround between floors, greatly improving construction efficiency on large-scale projects.

- Cost-Effectiveness: With standardized components, a high reuse rate, and simple operation, labor costs and material waste are reduced. The aluminium components also offer a high residual value after project completion.

- Environmentally Friendly: The system aligns with sustainable construction principles, minimizing waste and promoting reusable materials.

Table Formwork Factory in China

5. Installation and Operation Process

The installation process of the GETO truss-type table formwork is straightforward and well-structured:

- Preparation Work: Review design drawings, prepare necessary safety gear, and set up the installation site.

- Truss Installation: Use a tower crane to hoist the truss onto the crosstie and secure it with scissor braces, connecting boards, and bolts.

- Extension Frame Assembly: Connect extension parts to the main frame using bolts, raking shores, and accessories to achieve the required length.

- Aluminium Beam Installation: Position the aluminium beams into grooves and secure them with clamps.

- Formwork Placement: Lay the wooden panels perpendicular to the aluminium beams and fix them with rivets to ensure proper alignment.

- Handrail Installation: Attach the handrails to the frame for safety during slab pouring operations.

- Verticality Adjustment: Before casting concrete, adjust and inspect the verticality to maintain precision in slab construction.

Main Components:

- Truss

- Scissor Braces

- Aluminium Beam

- U-Type Connecting Parts

- Base Plate

- Top Support

- Hanging High Stand

- Double Round Pipe

- Bolts

Each component is precisely designed and standardized for easy assembly, consistent performance, and safe lifting operations.

GETO Table Formwork Applications

Building Smarter with GETO Table Formwork

As the demand for faster, safer, and more sustainable concrete construction continues to grow, table formwork systems play a vital role in shaping the future of modern buildings. The GETO truss-type table formwork system provides contractors with a reliable, efficient, and environmentally friendly solution for constructing cast-in-place reinforced concrete floor slabs of varying heights and complexities.

By combining strong materials, smart design, and simplified operation, GETO helps global construction teams achieve better project results—reducing time, cost, and labor without compromising quality. To explore tailored formwork and scaffolding solutions for your next project, contact GETO’s expert team at geto_market@geto.com.cn.