In high-rise construction, one key upgrade often comes from choosing the right Climbing Platform. It’s not just about safety and efficiency—it also reflects the industry's shift toward smarter and more integrated building solutions. Leading Climbing Platform Manufacturers are driving this progress with innovation and precision.

In this article, we highlight the top Climbing Platform manufacturers to watch in 2025. From company backgrounds to core technologies, this is your complete guide to the most reliable system providers in the market today.

Climbing Platform Manufacturer in China

Leading Climbing Platform Manufacturer in The World 2025

GETO Global Construction

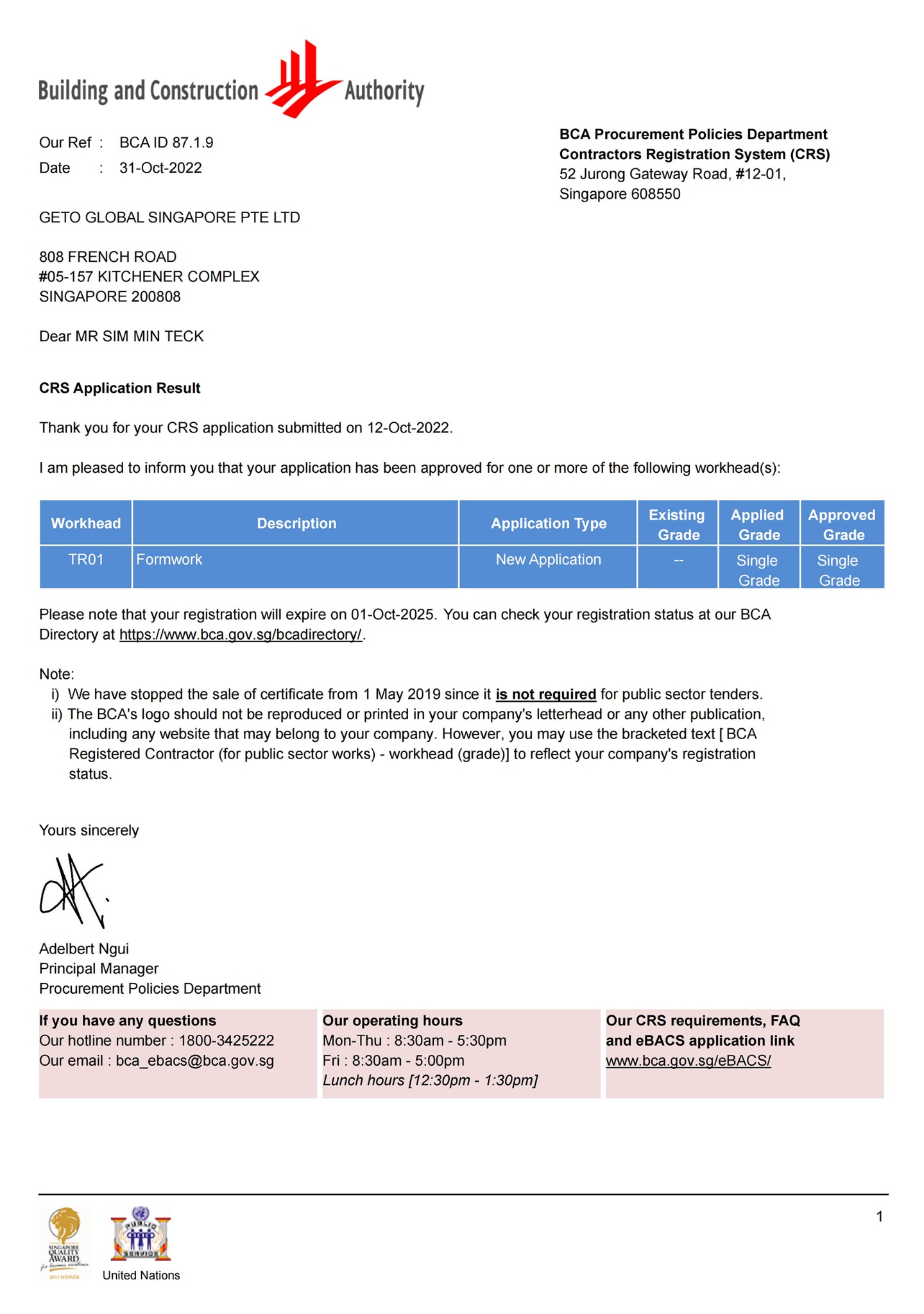

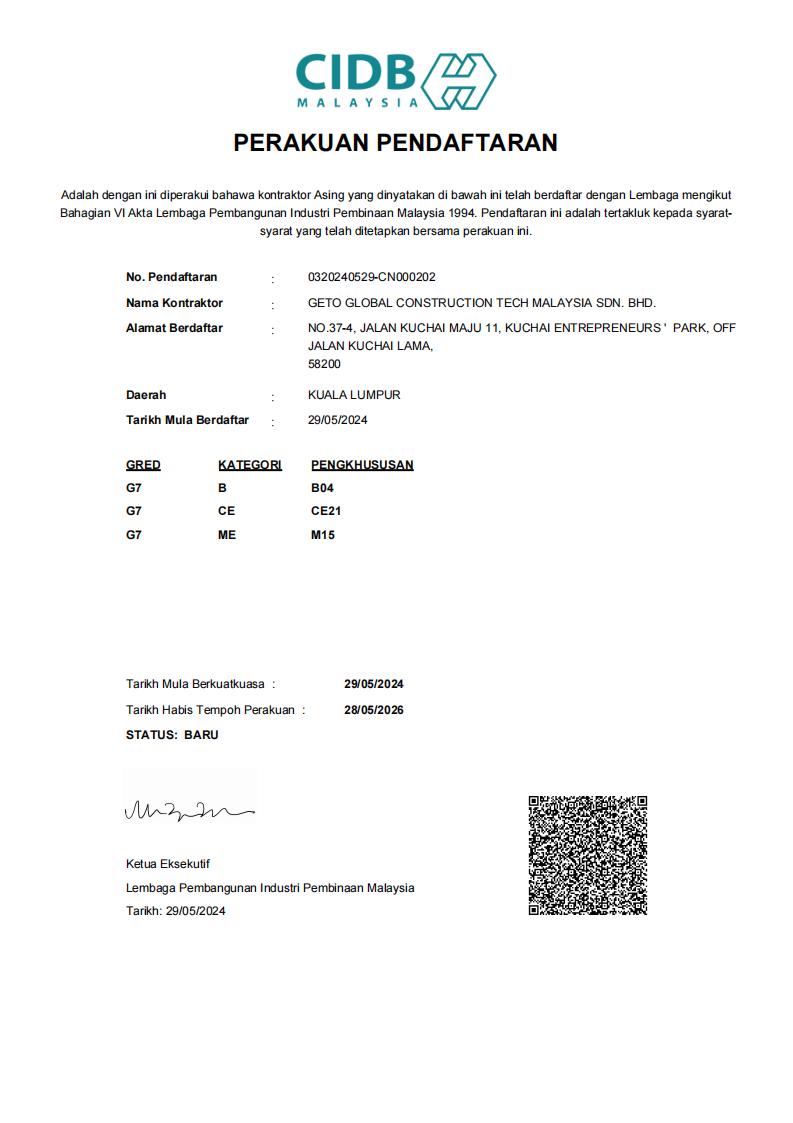

Headquarter: GETO China

Branch Office:GETO global singapore pte. ltd. & GETO global construction tech malaysia sdn bhd

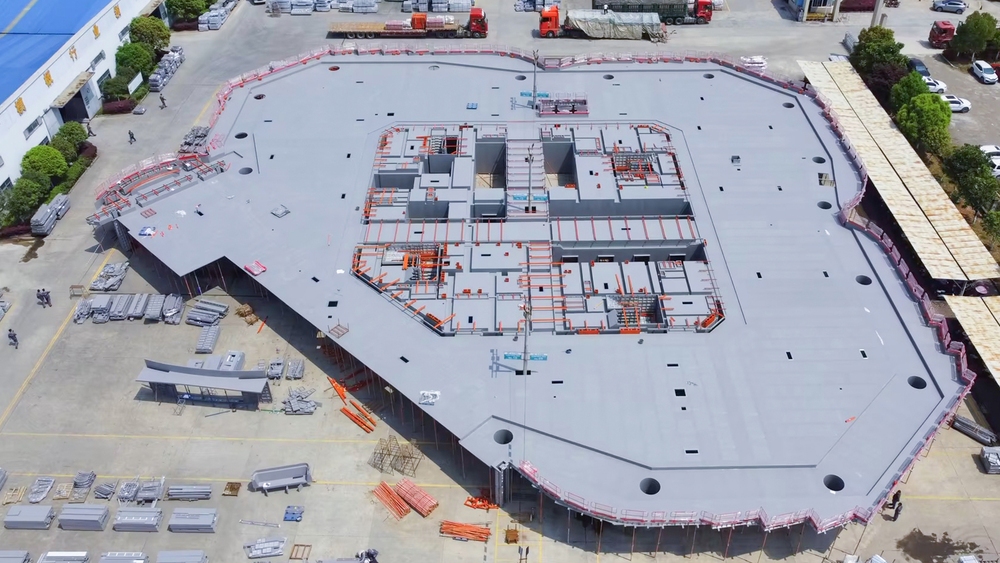

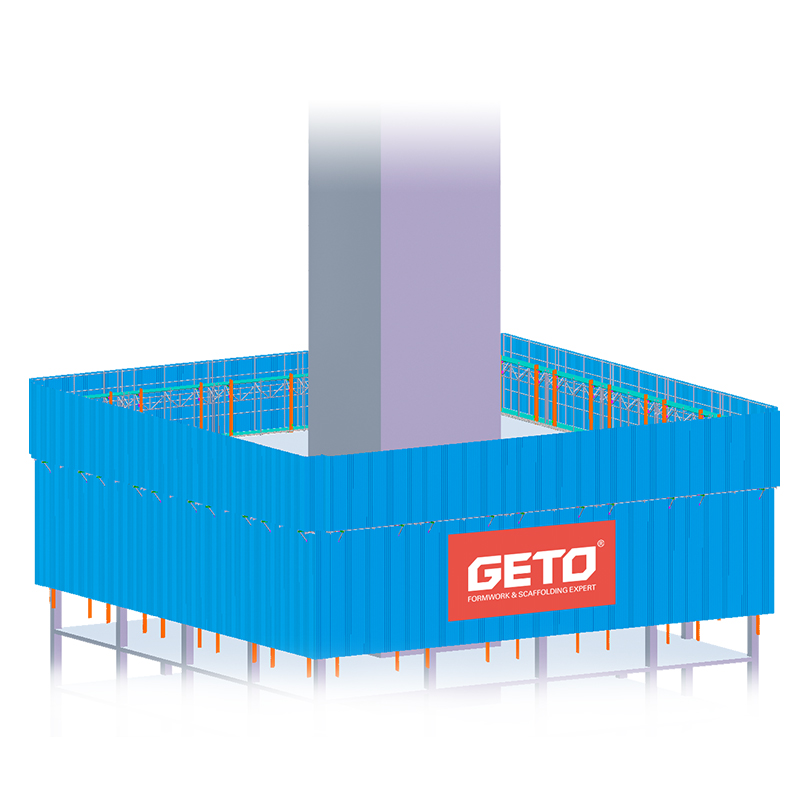

Founded in 2011, GETO has become a leading name in formwork and prefabricated building solutions. GETO is a China-based brand specializing in aluminum formwork, climbing platforms, and modular construction systems for global markets.

Other operations under the GETO umbrella include smart manufacturing bases, BIM technology services, and international logistics centers supporting projects in over 60 countries.

Type of Business: Design, Manufacturing, Construction Solutions

❖ Location: Zhongshan, Guangdong, China

❖ Year Established: 2011

Company Background and Advantage:

Established in 2011, GETO’s strength lies in its commitment to innovation, quality, and global reach. With advanced manufacturing facilities and cutting-edge BIM technology, GETO serves customers in over 60 countries, earning a strong reputation in the construction industry.

Products Offered: GETO specializes in aluminum formwork, climbing platforms, modular building systems, and related construction solutions.

What is Climbing Platform?

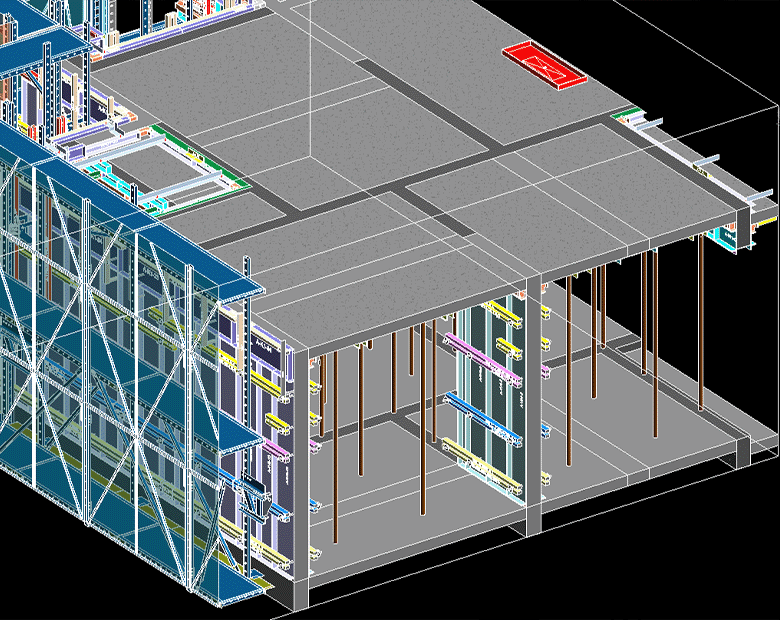

A Climbing Platform is a temporary, movable working platform used in high-rise construction projects. It is designed to safely support workers, materials, and equipment as the building progresses vertically. The platform “climbs” or moves upward along the structure, typically using hydraulic or mechanical systems, allowing continuous and efficient work at different heights without dismantling and rebuilding scaffolding. Climbing platforms improve construction safety, speed, and efficiency, especially in projects like tall buildings, bridges, and large infrastructure works.

Types of Climbing Platforms

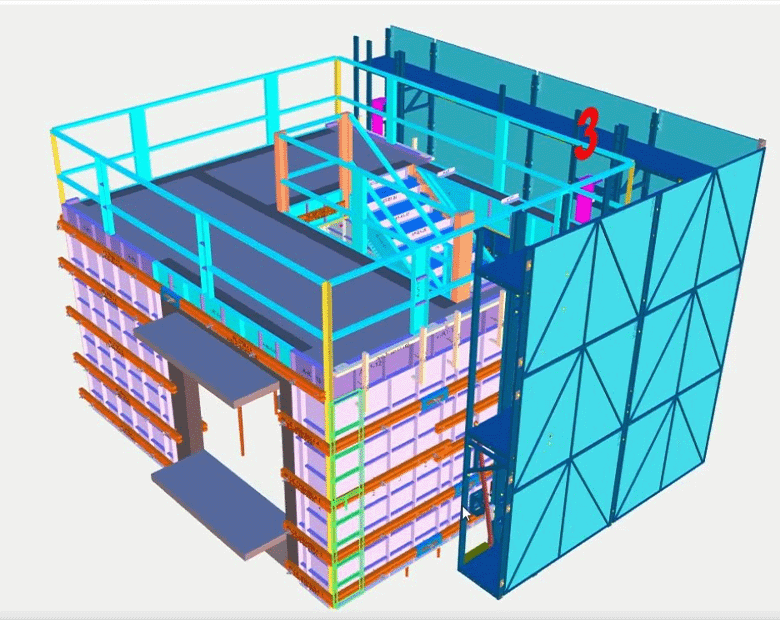

Hydraulic Climbing Platforms

Platforms that use hydraulic cylinders to lift and move the platform upward along the structure.

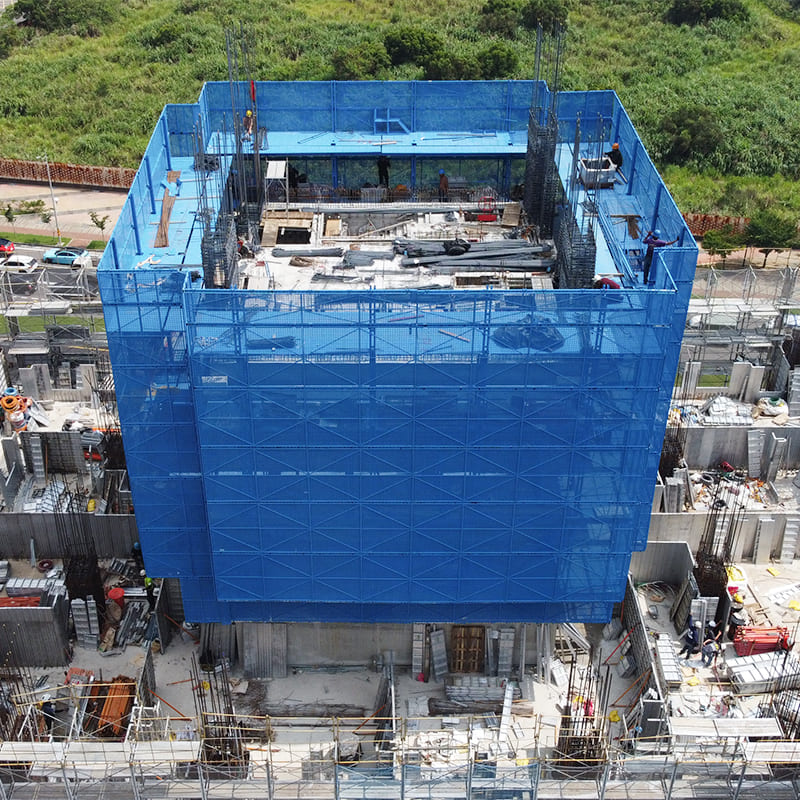

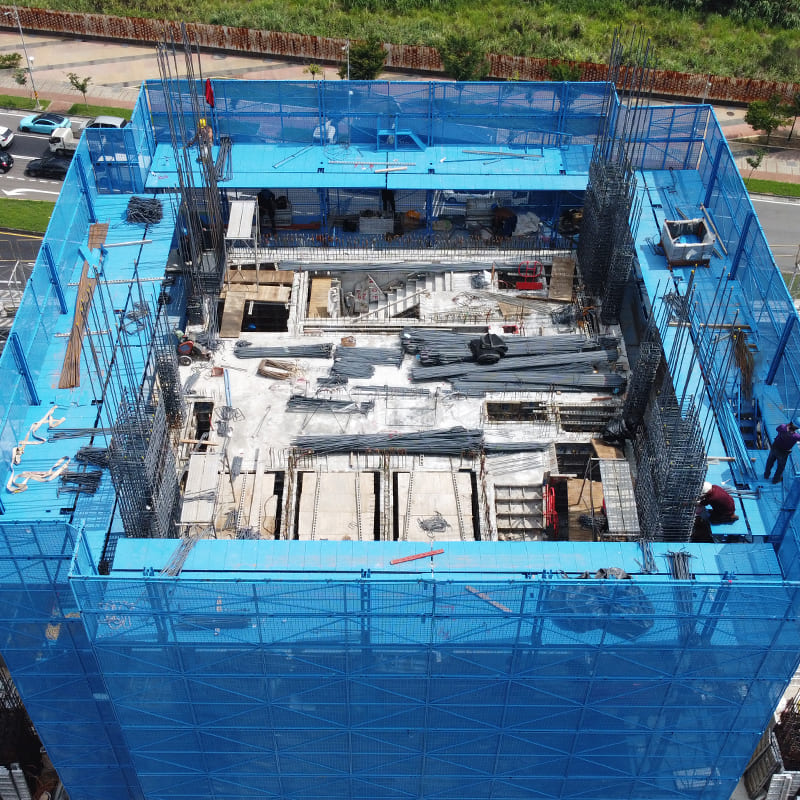

Hydraulic climbing platforms are widely used in high-rise building construction, bridge building, large infrastructure projects, and the installation and maintenance of industrial facilities. Powered by hydraulic systems, these platforms provide smooth vertical movement and offer workers a safe and stable working environment, significantly improving construction efficiency and safety, especially for projects requiring continuous high-altitude operations.

Mechanical Climbing Platforms

Platforms that rely on mechanical jacks or screw systems to climb the building framework.

Self-Climbing Platforms

Platforms that can climb automatically without external cranes, often integrated with the building structure for smooth movement.

Self-climbing platforms are widely used in the construction of high-rise buildings, towers, bridges, and large infrastructure projects. These platforms can climb automatically without the need for external cranes, making them highly efficient for continuous vertical construction work. They provide a safe and stable working environment for workers while improving overall construction speed and safety in complex, tall structures.

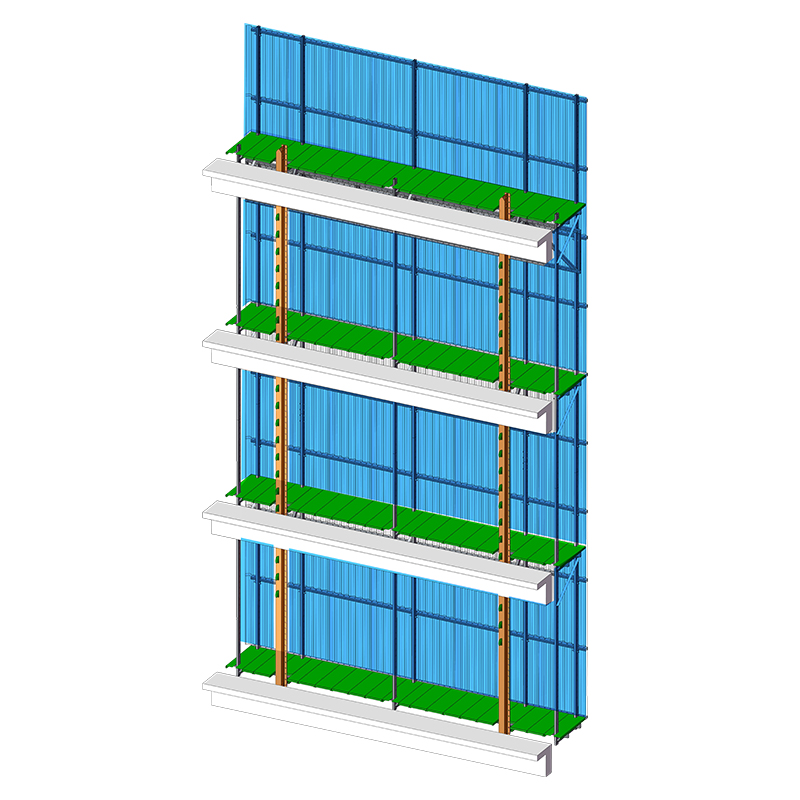

Supported Climbing Platforms

Platforms supported by external scaffolding or the building itself, which move upward as the construction progresses.

Suspended Climbing Platforms

Platforms suspended from the top of the building, which can be raised or lowered along the facade.

Each type serves specific construction needs and site conditions, helping to improve safety and efficiency on high-rise projects.

GETO also provides safety protection devices for climbing platforms

What is Safety protection device of climbing platform?

Safety protection devices of climbing platforms are various safety measures installed on the platform to prevent falls, falling objects, and abnormal platform movements. They ensure the safety of workers and equipment, making high-rise construction safer and more reliable.

These devices typically include:

Protection screens to prevent falling objects from injuring people;

Safety railings and protective nets to prevent personnel from falling;

Limit devices to stop the platform from moving beyond safe boundaries;

Emergency stop devices to quickly halt platform operation in abnormal situations;

Safety locking systems to ensure the platform remains stable and stationary during work.

Related Article:What is Protection Screen?

Analysis of the quality and durability advantages of Geto climbing platform

Geto climbing platform enjoys a good reputation in the industry for its excellent quality and outstanding durability.

The company strictly selects high-strength steel and high-quality alloy materials, combined with advanced CNC machining and welding technology to ensure that each component has a solid structure and precise precision. Through a strict quality control system and multiple durability tests, Geto climbing platform can effectively withstand wind loads, vibrations and long-term operating pressure in complex construction environments.

In addition, Geto uses advanced anti-corrosion coatings and surface treatment processes to greatly extend the product life and reduce maintenance requirements. These high-standard materials and processes ensure the stability and reliability of the climbing platform, provide customers with solid operating support, and help high-rise buildings and large-scale infrastructure projects to be completed safely and efficiently.

As the top climbing platform manufacturer, how does Geto ensure that the safety performance of climbing platforms meets industry-leading standards?

Geto attaches great importance to the safety performance of climbing platforms and regards it as a core element of product design and manufacturing.

The company strictly follows national and international safety standards, such as China's relevant construction standards and European EN standards, to ensure that each climbing platform meets or exceeds industry requirements in terms of structural strength, load-bearing capacity and stability.

Geto incorporates multiple safety protection devices in the design stage, including efficient protection screens, anti-fall safety nets, safety railings, limit devices and emergency parking systems to comprehensively prevent the risk of falling people and objects. At the same time, the platform is equipped with an advanced safety locking system to ensure that the platform is stable and immobile during operation to avoid accidental movement.

Geto also implements strict product testing and on-site testing to ensure that all safety equipment operates reliably. Through these strict safety measures, Geto maximizes the safety of construction workers and provides a solid safety barrier for high-rise building construction.

Final Thoughts on Climbing Platform Manufacturers

In conclusion, climbing platforms are essential equipment in high-rise construction, with their safety, durability, and efficiency directly impacting project progress and quality. As a leading manufacturer in the industry, GETO leverages advanced manufacturing technologies, high-quality materials, and strict safety standards to consistently deliver reliable and innovative solutions to customers worldwide.

Choosing a reputable and capable manufacturer like GETO not only enhances construction efficiency but also ensures the safety of workers, providing strong support for modern high-rise building projects.

Frequently Asked Questions

What is the service life of the Geto climbing platform? How often is it maintained?

The service life of Geto climbing platforms typically exceeds 15 years, thanks to the use of high-strength materials and advanced anti-corrosion treatments that effectively resist wind erosion, corrosion, and mechanical wear in harsh construction environments.

Regarding maintenance, it is recommended to perform routine inspections and upkeep quarterly, including tightening key structural components, lubricating moving parts, and checking the integrity of safety protection devices. Additionally, a comprehensive professional inspection should be conducted annually to ensure the platform’s performance and safety standards are consistently met, guaranteeing long-term stable operation.

Does Geto support customized design to meet the needs of different projects?

Geto offers customized design services to meet the specific needs of different clients and projects. Whether it’s platform size, load capacity, or safety protection features, Geto can provide tailor-made solutions based on the specific construction environment and customer requirements, ensuring that the climbing platform operates efficiently and safely under various complex conditions.

Is it easy and quick to install and disassemble the climbing platform? Is technical support provided?

Geto’s climbing platforms are designed for easy and quick installation and disassembly, minimizing downtime on construction sites. The modular design and clear instructions help streamline the process. Additionally, Geto provides comprehensive technical support, including on-site assistance and remote guidance, to ensure smooth setup and efficient operation throughout the project.

What are the restrictions on the construction environment in which the climbing platform is applicable?

Climbing platforms are suitable for high-rise buildings, bridges, and large infrastructure projects, requiring a stable structural support and solid anchoring surface. Extreme weather conditions or unstable structures may limit their use and require additional safety measures or customized solutions. A thorough site assessment and compliance with local safety regulations are essential to ensure safe operation and optimal performance.